Single row Slewing Ring/Slewing Bearing product introduction

The single-row gearless slewing bearing is a four-point angular contact ball bearing, a composite bearing that can withstand axial load, radial load and overturning moment. As a bearing manufacturer, DZE has accumulated more than ten years of manufacturing experience and has been rated as: a global leader in precision bearing suppliers;DZE is a China bearing factory,Serving global bearing manufacturers.

Features of slewing ring:

High speed;

Easy to install;

Good dustproof effect;

Simple structure, strong bearing capacity;

Long life;

Easy maintenance, good rustproof effect;

Slewing ring selection factors

LYDZ standard products have precision series, which can meet high precision requirements and can be used in special fields such as machine tools, material transportation, power transmission, radar and robots. Please provide the following when you contact LYDZ sales engineers:

● Whether end face runout control is required

● Whether precision gears are required

● Whether preload is applied to make the bearing reach zero clearance to improve bearing stiffness

● Controller diameter

● Whether tapered mounting holes are used

● Whether LYDZ special coating is required to obtain stronger corrosion resistance

LYDZ can also provide customized cross roller series high-precision bearings, which also include all the above features except LYDZ coating.

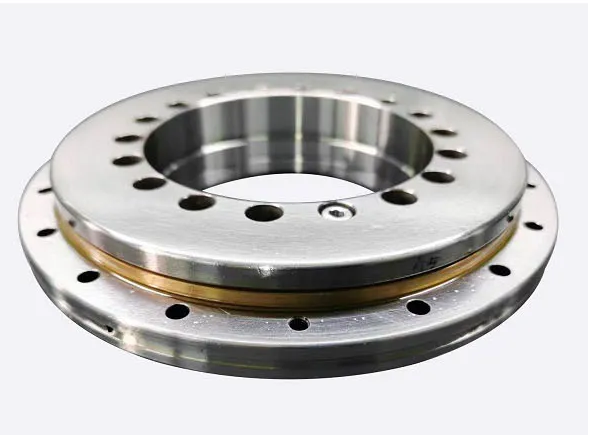

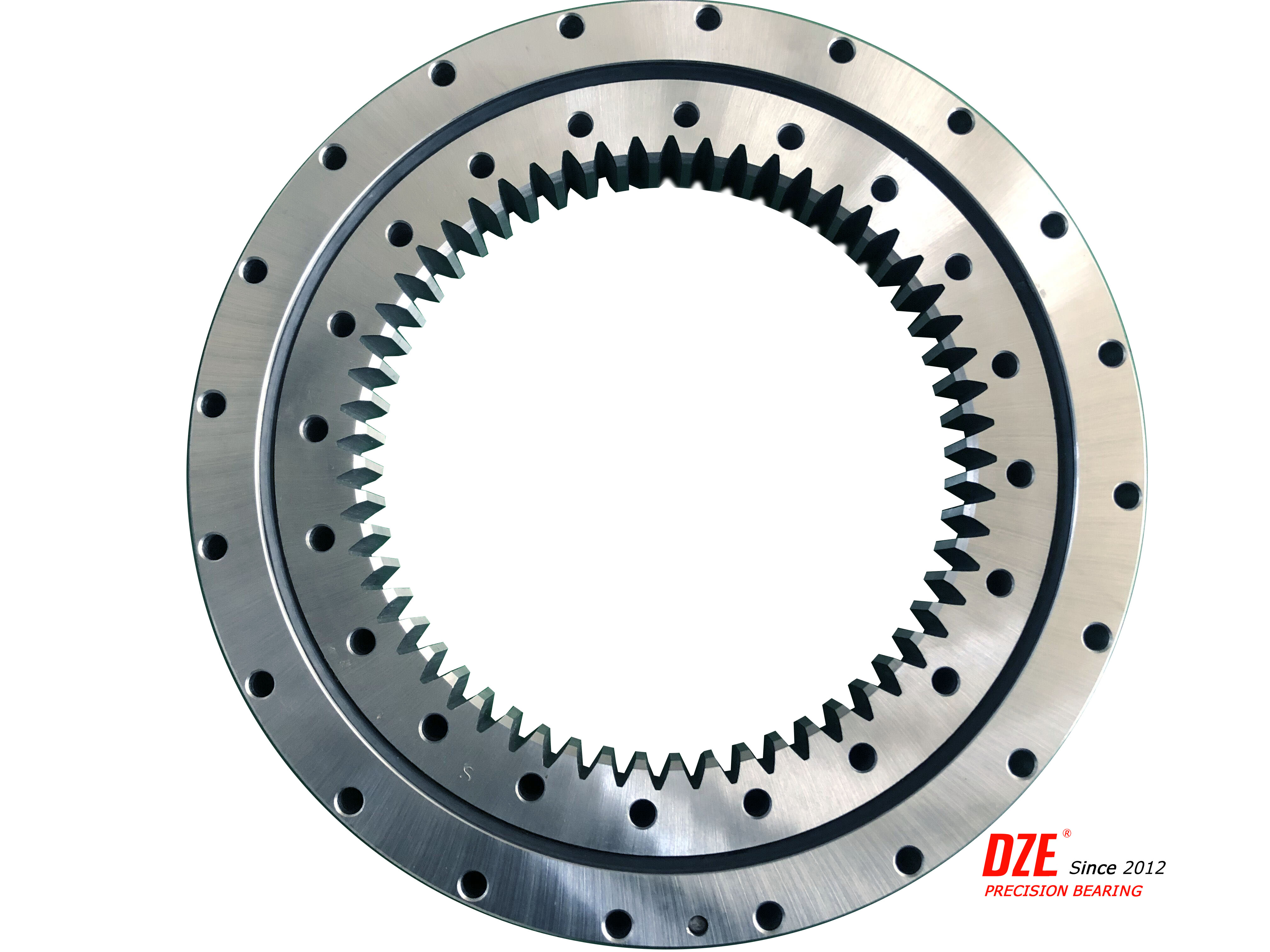

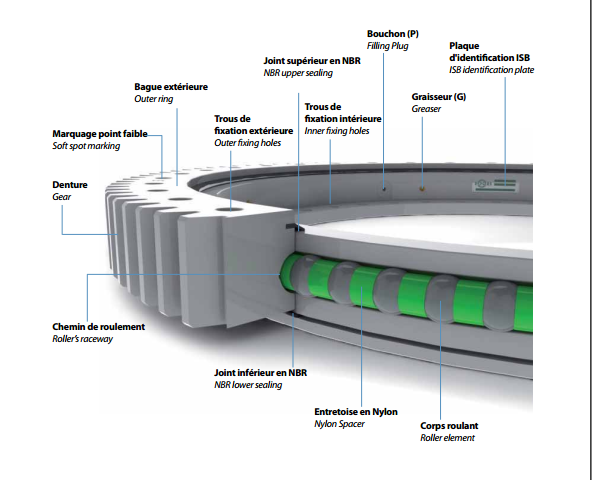

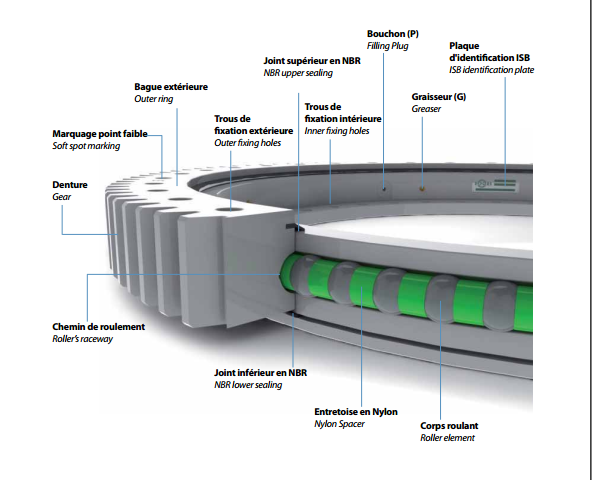

Slewing bearing structure

The structure of the precision slewing bearing produced by Luoyang DZE is as follows. If you want to change the structure, change the oil hole, pretend to seal, please call us: +8613700810892

Single row four point contact ball slewing bearing model parameters

外径D | 内径d | 高度H | 重量(KG) | 东轴型号 | 对应型号 | * |

| | | | Pdf格式 | | |

110 | 50 | 20 | 0.90 | LYDZ 00-110 | MTO-050 | STD |

135 | 65 | 22 | 1.85 | LYDZ 00-135 | MTO-065 | STD |

160 | 80 | 25 | 2.4 | LYDZ 00-160 | 010.10.120 | STD |

180 | 40 | 35 | 5 | LYDZ 00-180 | 10-16 0100/0-08000 | STD |

200 | 100 | 30 | 4.5 | LYDZ 00-200 | 010.10.150 | STD |

226 | 122 | 34 | 5.8 | LYDZ 00-226 | MTO-122/MTO-122T | STD |

234 | 125 | 35 | 7 | LYDZ 00-234 | 03 0181 07 | STD |

234 | 124.5 | 35 | 7 | VU140179 | STD |

249 | 143 | 34 | 6.9 | LYDZ 00-249 | MTO-143/MTO-143T | STD |

280 | 140 | 35 | 10 | LYDZ 00-280-L | 10-16 0200/0-08010 | STD |

280 | 120 | 60 | 20.5 | LYDZ 00-280 | 010.20.200 | STD |

290 | 150 | 41.5 | 14 | LYDZ 00-290-L | 03 0217 00 | STD |

290 | 200 | 24 | 5.4 | LYDZ 00-290 | VU130225 | STD |

300 | 145 | 50 | 17 | LYDZ 00-300 | MTO-145/MTO-145T | STD |

302 | 138 | 46 | 16 | LYDZ 00-302 | VU200220 | STD |

304 | 144 | 60 | 23 | LYDZ 00-304 | 010.20.224 | STD |

310 | 170 | 46 | 15 | LYDZ 00-310 | MTO-170/MTO-170T | STD |

329 | 190 | 45 | 17 | LYDZ 00-329 | 03.0260.00 | STD |

330 | 170 | 60 | 28 | LYDZ 00-330 | 010.20.250 | STD |

332 | 189 | 45 | 17 | LYDZ 00-332 | RKS.951145101001 | STD |

360 | 200 | 60 | 28.4 | LYDZ 00-360 | 010.20.280 | STD |

365 | 210 | 40 | 17.5 | LYDZ 00-365 | MTO-210/MTO-210T | STD |

380 | 240 | 35 | 14 | LYDZ 00-380 | 10-16 0300/0 08023 | STD |

380 | 270 | 35 | 12 | LYDZ 00-380-L | VU140325 | STD |

386 | 242 | 56 | 21 | LYDZ 00-386 | 10 20-0311 | STD |

VSU200311 | STD |

390 | 230 | 65 | 28 | LYDZ 00-390 | 10-22 0308 | STD |

418 | 204 | 56 | 19 | LYDZ 00-418-L | 90-20 0311 | SL |

VLU200311 |

420 | 265 | 50 | 25 | LYDZ 00-420 | MTO-265/MTO-265T | |

440 | 265 | 50 | 29 | LYDZ 00-440 | 03 0342 05 | STD |

455 | 265 | 71 | 45 | LYDZ 00-455 | 03 0360 00 | STD |

471 | 285 | 63 | 41 | LYDZ 00-471 | 10-25 0371 | |

475 | 335 | 45 | 30 | LYDZ 00-475 | RKS.901175101001 | STD |

480 | 340 | 35 | 23 | LYDZ 00-480 | 10-16 0400 | |

485 | 275 | 55 | 43 | LYDZ 00-485 | 10-25 0380 | |

486 | 342 | 56 | 29 | LYDZ 00-486 | 33 0411 01 | SLBP |

VSU200414 | |

RKS.060.20.414 | |

518 | 304 | 56 | 23 | LYDZ 00-518 | 23 0411 01 | 轻型 |

VLU200414 | |

RKS.23.0411 | |

520 | 324 | 60 | 48 | LYDZ 00-520 | MTO-324T | |

555 | 355 | 63 | 53 | LYDZ 00-555 | VSU250455 | |

577 | 370 | 75 | 68 | LYDZ 00-577 | 10-32 0474 | |

580 | 440 | 35 | 24 | LYDZ 00-580 | 10-16 0500 | |

616 | 472 | 56 | 38 | LYDZ 00-616 | 33 0541 01 | SLBP |

VSU200544 | |

RKS.060.20.0544 | |

626 | 424 | 72 | 70 | LYDZ 00-626 | 03 0525 01 | STD |

648 | 434 | 56 | 34 | LYDZ 00-648 | 23 0541 01 | 轻型 |

VLU200544 | |

RKS.23.0544 | |

655 | 455 | 63 | 65 | LYDZ 00-655 | VSU250555 | |

712 | 487 | 72 | 91 | LYDZ 00-712 | 03 0600 02 | STD |

716 | 572 | 56 | 45 | LYDZ 00-716 | 33 0641 01 | SLBP |

VSU200644 | |

RKS.060.20.0644 | |

748 | 534 | 56 | 40 | LYDZ 00-748 | 23 0641 01 | 轻型 |

VLU200644 |

RKS.23.0641 |

755 | 555 | 63 | 76 | LYDZ 00-755 | VSU250655 | |

800 | 560 | 82 | 120 | LYDZ 00-800 | | |

816 | 672 | 56 | 52 | LYDZ 00-816-L | 33 0741 01 | SLBP |

VSU200744 |

RKS.060.20.0744 |

848 | 634 | 56 | 46 | LYDZ 00-848 | 23 0741 01 | 轻型 |

VLU200744 |

RKS.23.0741 |

900 | 670 | 86 | 148 | LYDZ 00-900 | 03 0785 00 | STD |

916 | 772 | 56 | 60 | LYDZ 00-916 | 33 0841 01 | SLBP |

916 | 772 | 56 | 60 | VSU200844 | |

916 | 772 | 56 | 60 | RKS.060.20.0844 | |

948 | 734 | 56 | 52 | LYDZ 00-948 | 23 0841 01 | 轻型 |

948 | 734 | 56 | 52 | VLU200844 | |

948 | 734 | 56 | 52 | RKS.23.0844 | |

1016 | 872 | 56 | 67 | LYDZ 00-1016 | 33 0941 01 | SLBP |

1016 | 872 | 56 | 67 | VSU200944 |

1016 | 872 | 56 | 67 | RKS.060.20.0944 |

1048 | 834 | 56 | 58 | LYDZ 00-1048 | 23 0941 01 | 轻型 |

1048 | 834 | 56 | 58 | VLU200944 |

1048 | 834 | 56 | 58 | RKS.23.0944 |

1100 | 805 | 90 | 131 | LYDZ 00-1100 | VLU300955 | |

1130 | 845 | 100 | 271 | LYDZ 00-1130 | 03 0980 02 | STD |

1166 | 1022 | 56 | 78 | LYDZ 00-1094 | 33 1091 01 | SLBP |

1166 | 1022 | 56 | 78 | VSU201094 |

1166 | 1022 | 56 | 78 | RKS.060.20.1094 |

1198 | 984 | 56 | 67 | LYDZ 00-1198 | VLU201094 | 轻型 |

1198 | 984 | 56 | 67 | RKS.23.1094 |

1198 | 984 | 56 | 67 | 23 1091 01 |

Overview of slewing bearing production

The production of precision slewing bearings covers raw material selection, forging heat treatment, turning, mounting hole processing, gear processing, rolling element selection, precision grinding, assembly, finished product inspection, packaging, etc. DZE Precision Bearing Factory is equipped with advanced manufacturing assembly, strict testing process and quality control,Ensure the quality and performance of bearings.

Material selection: Precision turntable bearings are mostly made of bearing steel, high-quality alloy steel or stainless steel. These materials have high wear resistance, high strength and corrosion resistance.

2. Production and processing: The design of slewing bearings needs to take into account the dynamic load, movement speed, precision and other factors in actual work. Therefore, high-precision grinders are required to ensure the dimensional accuracy and rotation accuracy of the bearings.

3. Heat treatment: To improve the hardness and wear resistance of the bearing, DZE bearings heat treat the inner and outer rings of the slewing bearings, including high-frequency quenching, overall quenching, laser quenching, etc.

4. Assembly and testing: The assembly requirements of the turntable bearing are very strict to ensure the matching accuracy. After the assembly is completed, strict testing is required to ensure the performance and life of the bearing.