RE series thin-walled cross roller bearings-DZE Bearing rust prevention

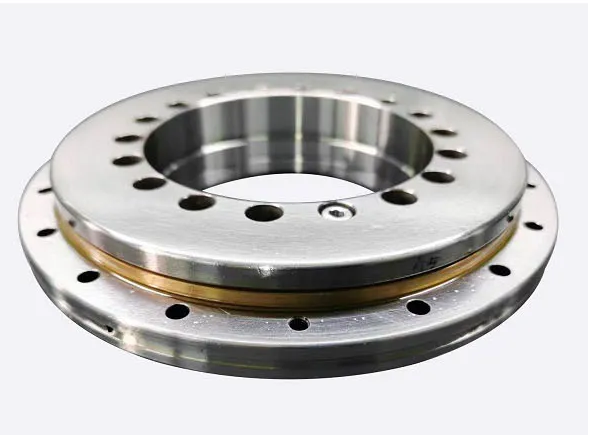

RE cross roller bearings and bearing packaging due to the segmented inner or outer ring, are fixed together with the cross roller collar after installing the rollers and spacers to prevent mutual separation, so the installation of the cross roller collar is simple to operate. Due to the cross arrangement of rollers, only one set of cross roller collars is needed to withstand loads in all directions, which increases the rigidity by 3-4 times compared to traditional models. Meanwhile, due to the fact that the inner or outer ring of the cross roller bearing is a two-part structure, the bearing clearance can be adjusted, allowing for high-precision rotational motion even when preloaded.

1. Has excellent rotational accuracy The internal structure of the cross roller bearing adopts rollers arranged in a 90 degree perpendicular cross arrangement.The RE series cross roller bearing rust prevention measures Otherwise, it will have a significant impact on the lifespan of the bearing

2. Simplified operation and installationThe outer or inner ring, which is divided into two parts, is fixed together after installing the rollers and retainers, so the installation process is very simple.

3. Endure significant axial and radial loads .For example: RE30040UUCCO P5 crossed roller bearing.

4. Significantly save installation space.Bearing packaging

5. High rotational speed capability.The maximum speed of RE60040 can reach 300 revolutions per minute

6. Reduce shaft length and processing costs, as thermal expansion leads to limited changes in geometric dimensions

7. Nylon divider is used, with low moment of inertia, low starting torque, and easy control of angular division

8. Optimize preload force, high stiffness, and high precision of guide roller operation

9. Permeable carbon steel provides excellent impact resistance and surface wear resistance

10. Bearing grease-Simple but well lubricated

Bearing characteristics:

1. High precision: The accuracy can reach P4 and P2 levels;

2. High rigidity: All bearings in this series are preloaded;

3. High load-bearing capacity: capable of withstanding axial loads, radial loads, and overturning loads.

4. Small size: This bearing has a small volume, which can save space for the host.

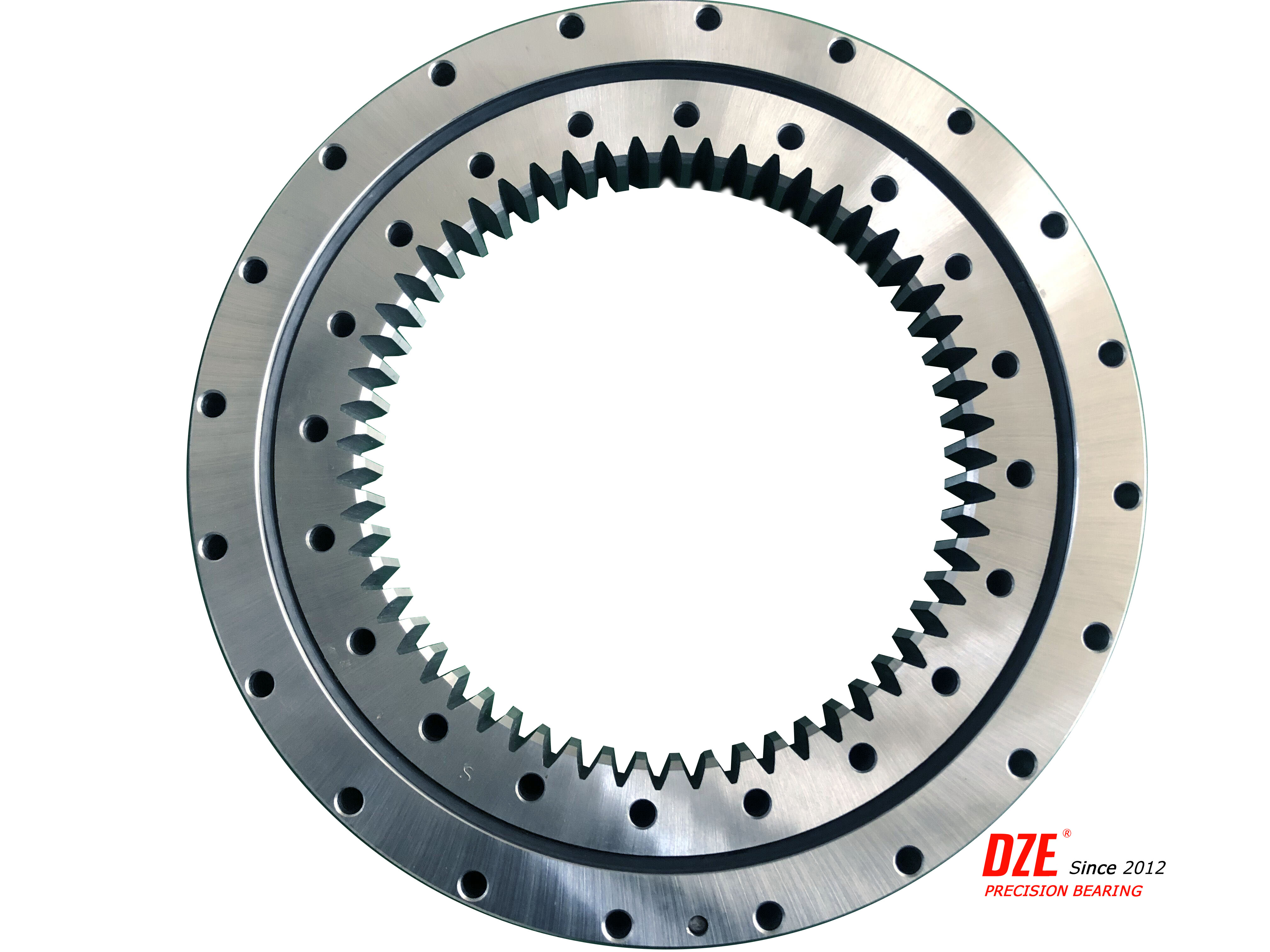

The RE series thin-walled cross roller bearings (outer ring integral, inner ring split) are also the basic type of cross roller bearings, with the same external dimensions as the RB type. The structure is an integral inner ring and the outer ring is divided into two pieces. It is particularly suitable for situations that require outer ring rotation accuracy.

Scope of application: Widely used in precision rotating workbenches, mechanical arm rotating joints, medical equipment, measuring instruments, and so on.

Lubrication: The cross roller bearings produced by our company are injected with high-quality imported German grease before leaving the factory, so they can be directly installed and used. However, this bearing has a smaller internal space than ordinary roller bearings, so it is necessary to regularly replenish lubricating grease. Inject lubricating grease through the oil holes located on the inner and outer rings. The supplementary interval is usually every 6 months to one year. When adding lubricating grease, please use the same type of grease to supplement. At the same time, after the bearing is installed, due to the resistance of the grease, the initial rotational torque of the bearing will be relatively large in a short period of time. However, when excess grease overflows from the sealing part, the torque value will return to normal.

Precautions for use:

The divided inner or outer ring cannot be separated after being fixed with bolts and nuts, and can be directly installed into the bearing seat for use. Meanwhile, if the isolation block inside the bearing is assembled incorrectly, it will have a significant impact on the rotational performance and rolling element stress, so please do not disassemble the bearing casually.

1. The seams of the inner or outer ring may sometimes deviate to some extent. Before installing the bearing seat, please loosen the bolts that fix the inner or outer ring, correct them with a plastic hammer, and then proceed with installation.

2. Please do not apply external force to the connecting bolts during installation or disassembly.

3. Please pay attention to the dimensional tolerances of the installation components, so that the side clamping flange can press the inner or outer ring tightly from the side.

RE Cross Roller Bearing-bearing grease

RE Cross Roller Bearing Parameters

Shaft Diameter | Model | External Dimensions | Size | Load | Load | Weight |

inner | outside | Center Diameter | Height | Holes | r | ds | Dh | C | Co | Kg |

d | D | DP | B/B1 | a | b | KN | KN |

50 | RE 5013 | 50 | 80 | 66 | 13 | 2.5 | 1.6 | 1 | 57.5 | 72 | 16.7 | 20.9 | 0.27 |

60 | RE 6013 | 60 | 90 | 76 | 13 | 2.5 | 1.6 | 1 | 68 | 82 | 18 | 24.3 | 0.3 |

70 | RE 7013 | 70 | 100 | 86 | 13 | 2.5 | 1.6 | 1 | 78 | 92 | 19.4 | 27.7 | 0.35 |

80 | RE 8016 | 80 | 120 | 101.4 | 16 | 3 | 1.6 | 1 | 91 | 111 | 30.1 | 42.1 | 0.7 |

90 | RE 9016 | 90 | 130 | 112 | 16 | 3 | 1.6 | 1.5 | 98 | 118 | 31.4 | 45.3 | 0.75 |

100 | RE10016 | 100 | 140 | 121.1 | 16 | 3 | 1.6 | 1.5 | 109 | 129 | 31.7 | 48.6 | 0.83 |

RE 10020 | 150 | 127 | 20 | 3.5 | 1.6 | 1.5 | 113 | 133 | 33.1 | 50.9 | 1.45 |

110 | RE 11012 | 110 | 135 | 123.3 | 12 | 2.5 | 1 | 1 | 117 | 127 | 12.5 | 24.1 | 0.4 |

RE 11015 | 145 | 129 | 15 | 3 | 1.6 | 1 | 122 | 136 | 23.7 | 41.5 | 0.75 |

RE 11020 | 160 | 137 | 20 | 3.5 | 1.6 | 1.5 | 120 | 140 | 34 | 54 | 1.56 |

120 | RE 12016 | 120 | 150 | 136 | 16 | 3 | 1.6 | 1 | 127 | 141 | 24.2 | 43.2 | 0.72 |

RE 12025 | 180 | 152 | 25 | 3.5 | 2 | 2 | 133 | 164 | 66.9 | 100 | 2.62 |

130 | RE 13015 | 130 | 160 | 146 | 15 | 3 | 1.6 | 1 | 137 | 152 | 25 | 46.7 | 0.72 |

RE 13025 | 190 | 162 | 25 | 3.5 | 2 | 2 | 143 | 174 | 69.5 | 107 | 2.82 |

140 | RE 14016 | 140 | 175 | 160 | 16 | 3 | 1.6 | 1.5 | 147 | 162 | 25.9 | 50.1 | 1 |

RE 14025 | 200 | 172 | 25 | 3.5 | 2 | 2 | 154 | 185 | 74.8 | 121 | 2.96 |

150 | RE 15013 | 150 | 180 | 166 | 13 | 2.5 | 1.6 | 1 | 158 | 172 | 27 | 53.5 | 0.68 |

RE 15025 | 210 | 182 | 25 | 3.5 | 2 | 2 | 164 | 194 | 76.8 | 128 | 3.16 |

RE 15030 | 230 | 192 | 30 | 4.5 | 3 | 2 | 173 | 210 | 100 | 156 | 5.3 |

160 | RE 16025 | 160 | 220 | 192 | 25 | 3.5 | 2 | 2 | 173 | 204 | 81.7 | 135 | 3.14 |

170 | RE 17020 | 170 | 220 | 196.1 | 20 | 3.5 | 1.6 | 2 | 184 | 198 | 29 | 62.1 | 2.21 |

180 | RE 18025 | 180 | 240 | 210 | 25 | 3.5 | 2 | 2 | 195 | 225 | 84 | 143 | 3.44 |

190 | RE 19025 | 190 | 240 | 219 | 25 | 3.5 | 1.6 | 1.5 | 202 | 222 | 41.7 | 82.9 | 2.99 |

200 | RE 20025 | 200 | 260 | 230 | 25 | 3.5 | 2 | 2.5 | 215 | 245 | 84.2 | 157 | 4 |

RE 20030 | 280 | 240 | 30 | 4.5 | 3 | 2.5 | 221 | 258 | 114 | 200 | 6.7 |

RE 20035 | 295 | 247.7 | 35 | 5 | 3 | 2.5 | 225 | 270 | 151 | 252 | 9.6 |

220 | RE 22025 | 220 | 280 | 250.1 | 25 | 3.5 | 2 | 2.5 | 235 | 265 | 92.3 | 171 | 4.1 |

240 | RE 24025 | 240 | 300 | 272.5 | 25 | 3.5 | 2 | 3 | 256 | 281 | 68.3 | 145 | 4.5 |

250 | RE 25025 | 250 | 310 | 280.9 | 25 | 3.5 | 2 | 3 | 268 | 293 | 69.3 | 150 | 5 |

RE 25030 | 330 | 237.5 | 30 | 4.5 | 3 | 3 | 269 | 306 | 126 | 244 | 8.1 |

RE 25040 | 355 | 300.7 | 40 | 6 | 3.5 | 3 | 275 | 326 | 195 | 348 | 14.8 |

300 | RE 30025 | 300 | 360 | 332 | 25 | 3.5 | 2 | 3 | 319 | 344 | 75.7 | 178 | 5.9 |

RE 30035 | 395 | 345 | 35 | 5 | 3 | 3 | 322 | 368 | 183 | 367 | 13.4 |

RE 30040 | 405 | 351.6 | 40 | 6 | 3.5 | 3 | 326 | 377 | 212 | 409 | 17.2 |

350 | RE 35020 | 350 | 400 | 376.6 | 20 | 3.5 | 1.6 | 3 | 363 | 383 | 54.1 | 143 | 3.9 |

400 | RE 40035 | 400 | 480 | 440.3 | 35 | 5 | 3 | 3.5 | 422 | 459 | 156 | 370 | 14.5 |

RE 40040 | 510 | 453.4 | 40 | 6 | 3.5 | 3.5 | 428 | 479 | 241 | 531 | 23.5 |

450 | RE 45025 | 450 | 500 | 476.6 | 25 | 3.5 | 1.6 | 1.5 | 464 | 484 | 61.7 | 182 | 6.6 |

500 | RE 50025 | 500 | 550 | 526.6 | 25 | 3.5 | 1.6 | 1.5 | 514 | 534 | 65.5 | 201 | 7.3 |

RE 50040 | 600 | 548.8 | 40 | 6 | 3 | 3.5 | 526 | 572 | 239 | 607 | 26 |

RE 50050 | 625 | 561.6 | 50 | 6 | 3.5 | 3.5 | 536 | 587 | 267 | 653 | 41.7 |

600 | RE 60040 | 600 | 700 | 650 | 40 | 6 | 3 | 4 | 627 | 673 | 264 | 721 | 29 |