Quality Bearings-Slewing Ring Gear

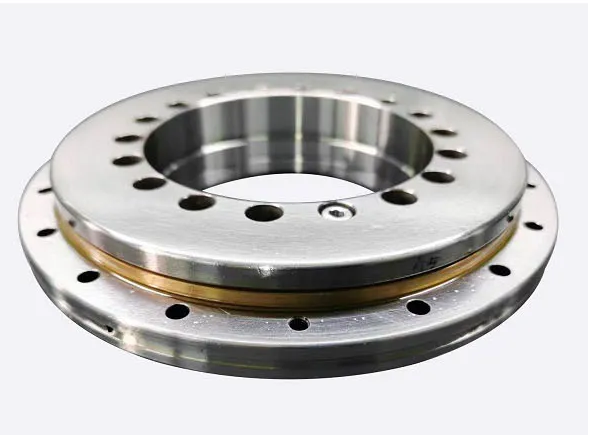

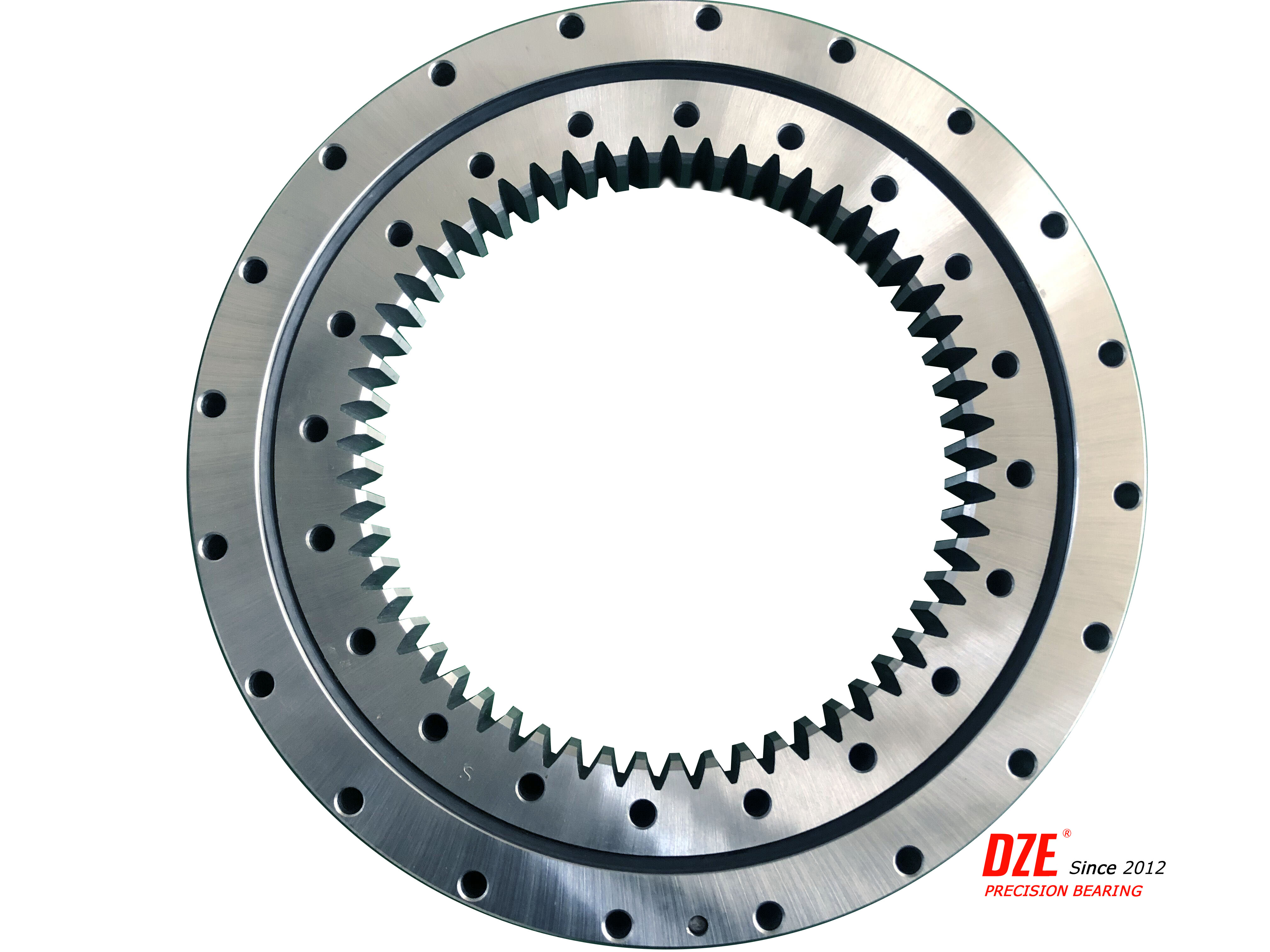

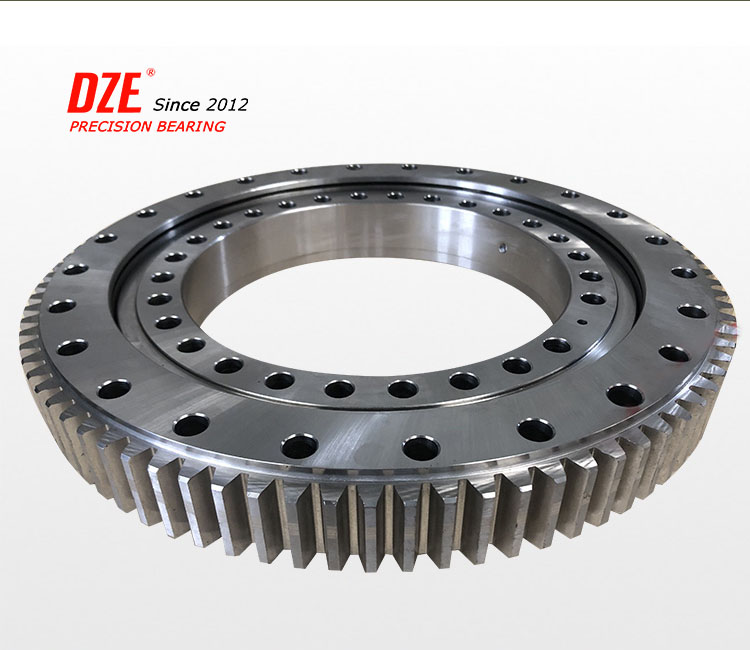

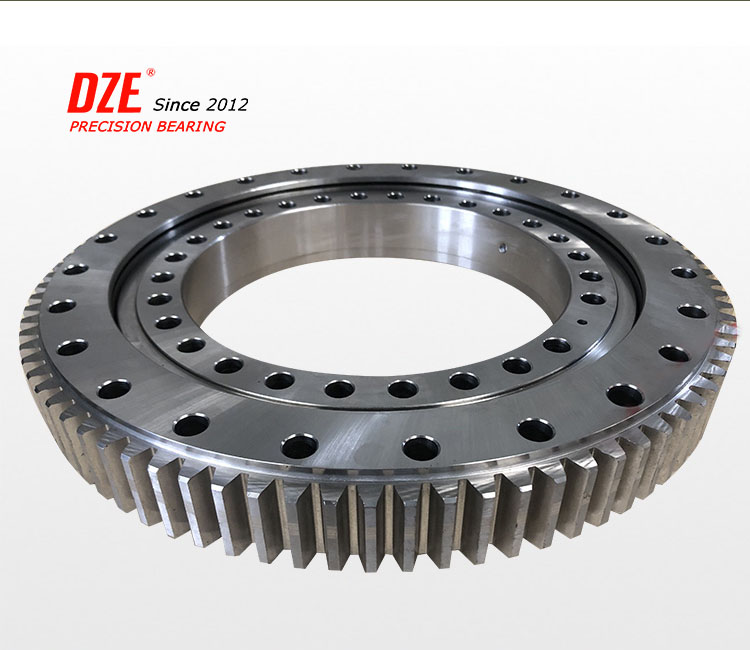

Slewing ring gear consist of an inner ring, an outer ring, rolling elements, seals and usually contain a gear. Both rings have connecting holes, which allow for optimized power transmission and simple and fast connection of adjacent machine parts. Quality bearings raceways together with the rolling elements and cages or spacers are designed to withstand loads acting alone or in combination, and in any direction.

DZE bearing manufacturers standard and custom slewing bearings quality bearings in various designs with outer diameters ranging from 30 mm to 2000 mm to meet the needs of specific applications.

What is a slewing ring?

Slewing rings are usually large-sized ball bearings or roller bearings and are quality bearings with very high load-bearing capacity and are suitable for oscillating and slow rotational movements. The bearings are mainly mounted in a horizontal position and are used to support axial forces and large tilting moments.

Radial loads occur only to a minor extent. The bearing ring is usually mounted directly on the direct part of the adjacent structure with screws. The inner or outer ring can be provided with teeth to facilitate drive solutions, also called slewing ring gears. Slewing rings are usually loaded with occasional rotational movements, slow rotational movements, slow rotation or at standstill, and their size is mainly based on their static load-bearing capacity.

Quality bearings are used for the support of excavators (in this case as a connecting element between the upper and lower structure), cranes (e.g. as azimuth slewing bearings), blade and tower adjustment in wind power generation and many other areas of heavy machinery construction. They are used in applications where high loads are present and significant operating safety is required. Small slewing bearings with high precision, quality bearings are also used in robots and robot drives.

DZE is a bearing manufacturer. The production series include VSU200 series, VSA200 series, and VSI200 series.

Advantages of slewing bearings

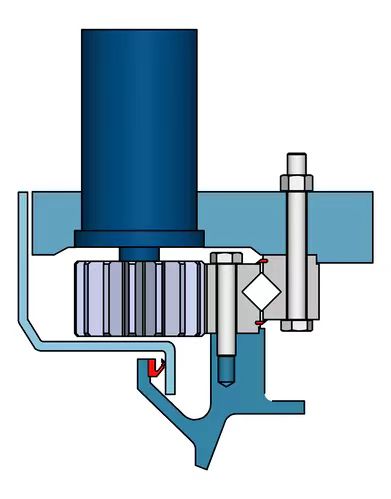

Slewing rings offer many advantages over traditional bearing assemblies and are increasingly being used as standard machine components. These include reduced part count, simplified machining, quick and easy assembly, reduced space requirements and lower overall weight.

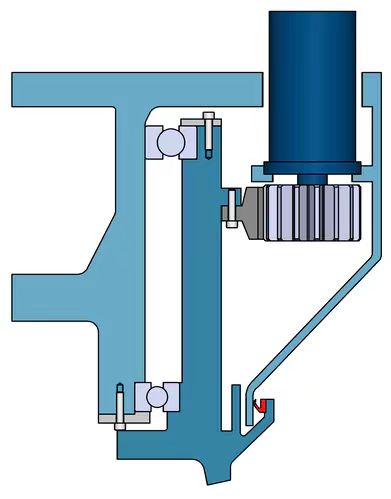

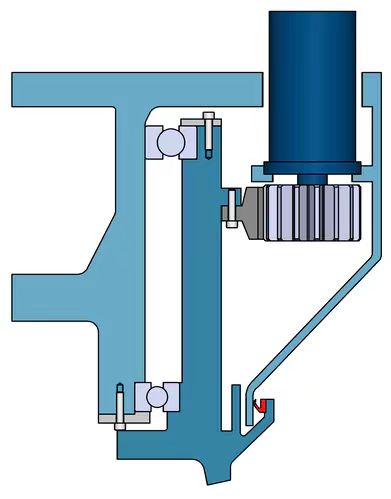

System with a slewing bearing ring

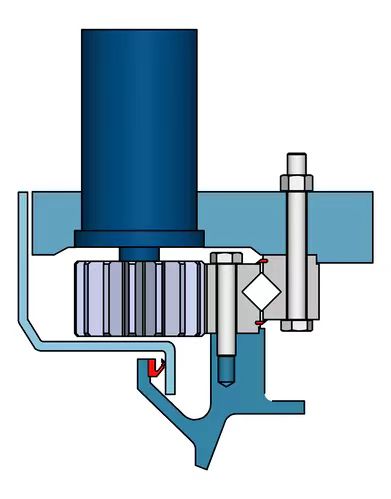

System without a slewing bearing ring