-

Home

- About DZE

-

Products

-

Untoothed Single Row Ball Slewing Rings

-

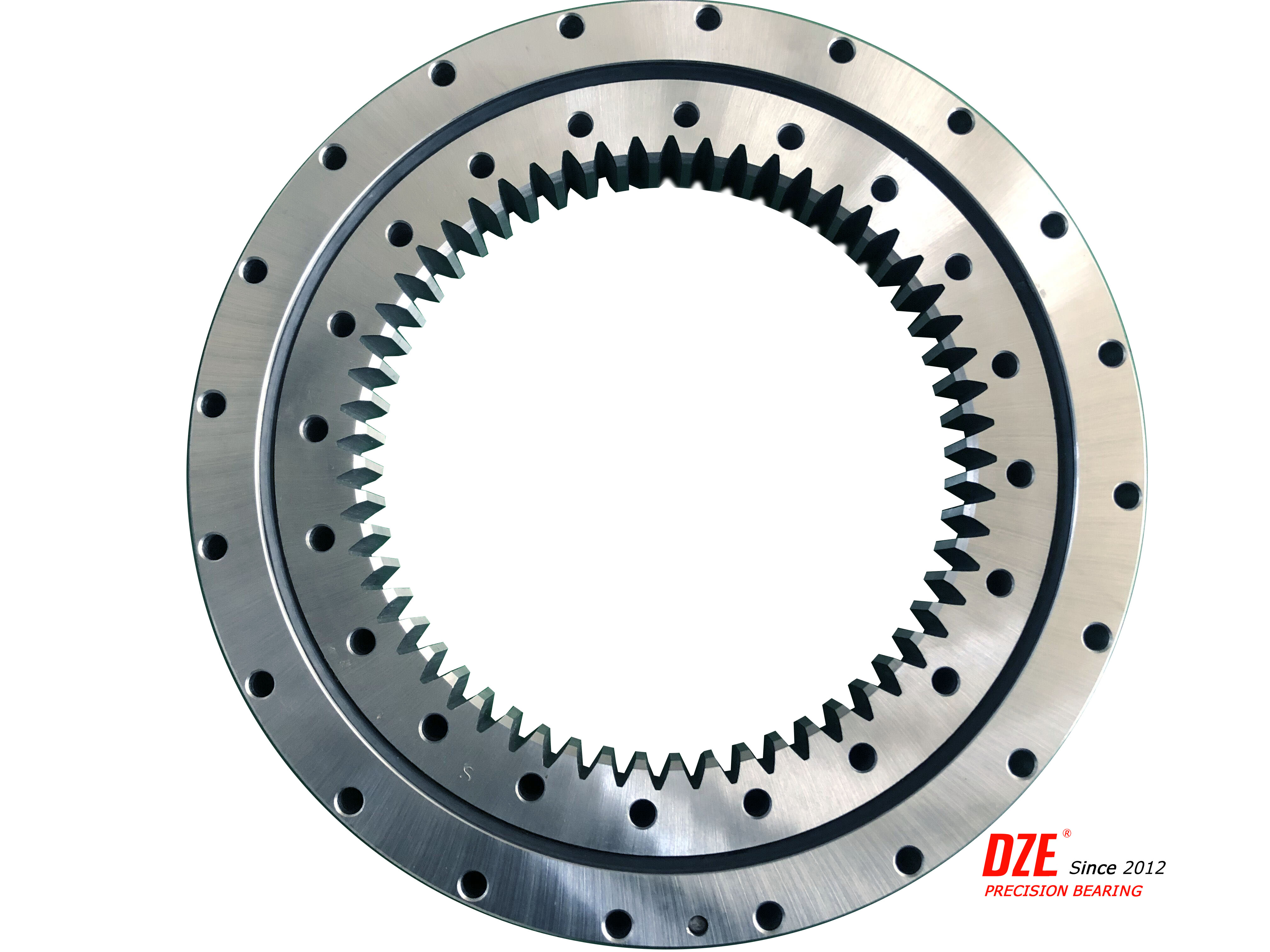

External Gear Four Point Contact Ball Slewing Bearing

-

Internal Toothed One Row Ball Bearing

-

Gearless Crossed Roller Slewing Bearing

-

External Gear Crossed Roller Slewing Bearing

-

Internal Gear Crossed Roller Slewing Bearing

-

Cross Roller Bearings

-

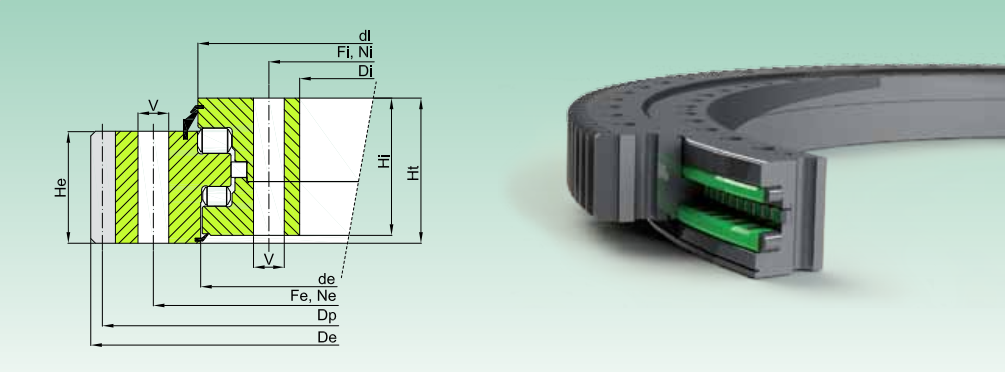

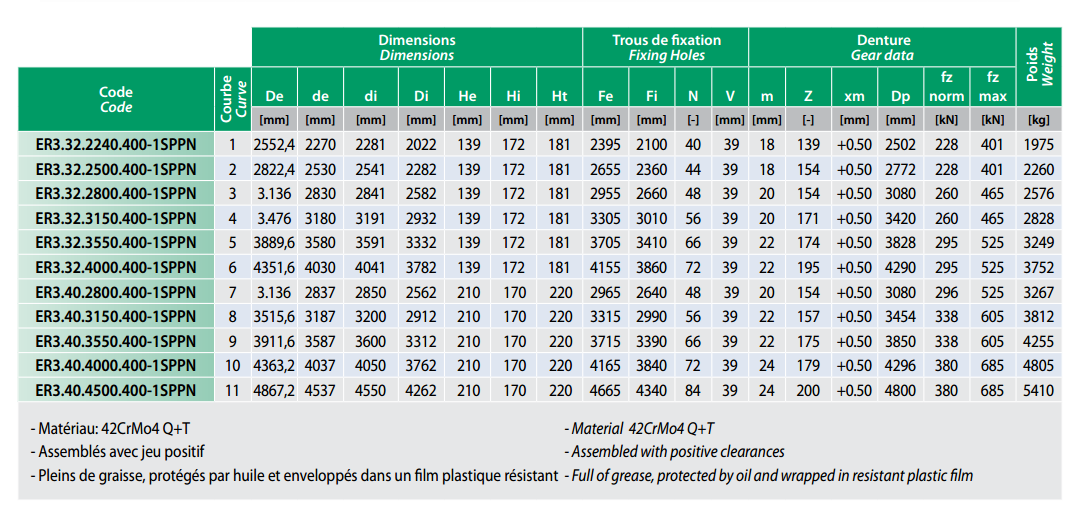

Triple-row Roller Slewing Rings

-

Double Row Ball Slewing Bearing

-

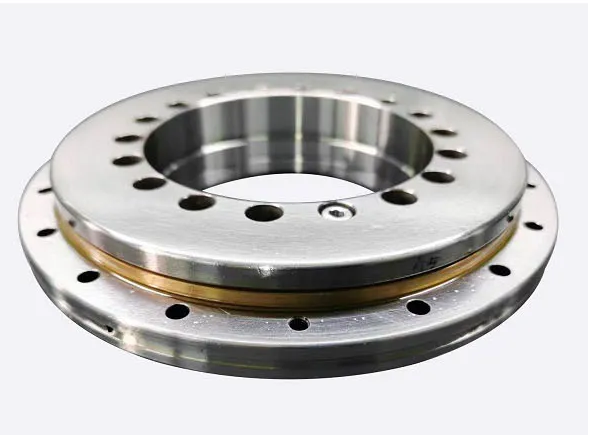

YRT Precision Rotary Table Bearings

-

Untoothed Single Row Ball Slewing Rings

- News

-

Case

- Factory Show

-

Contact Us

-

Video