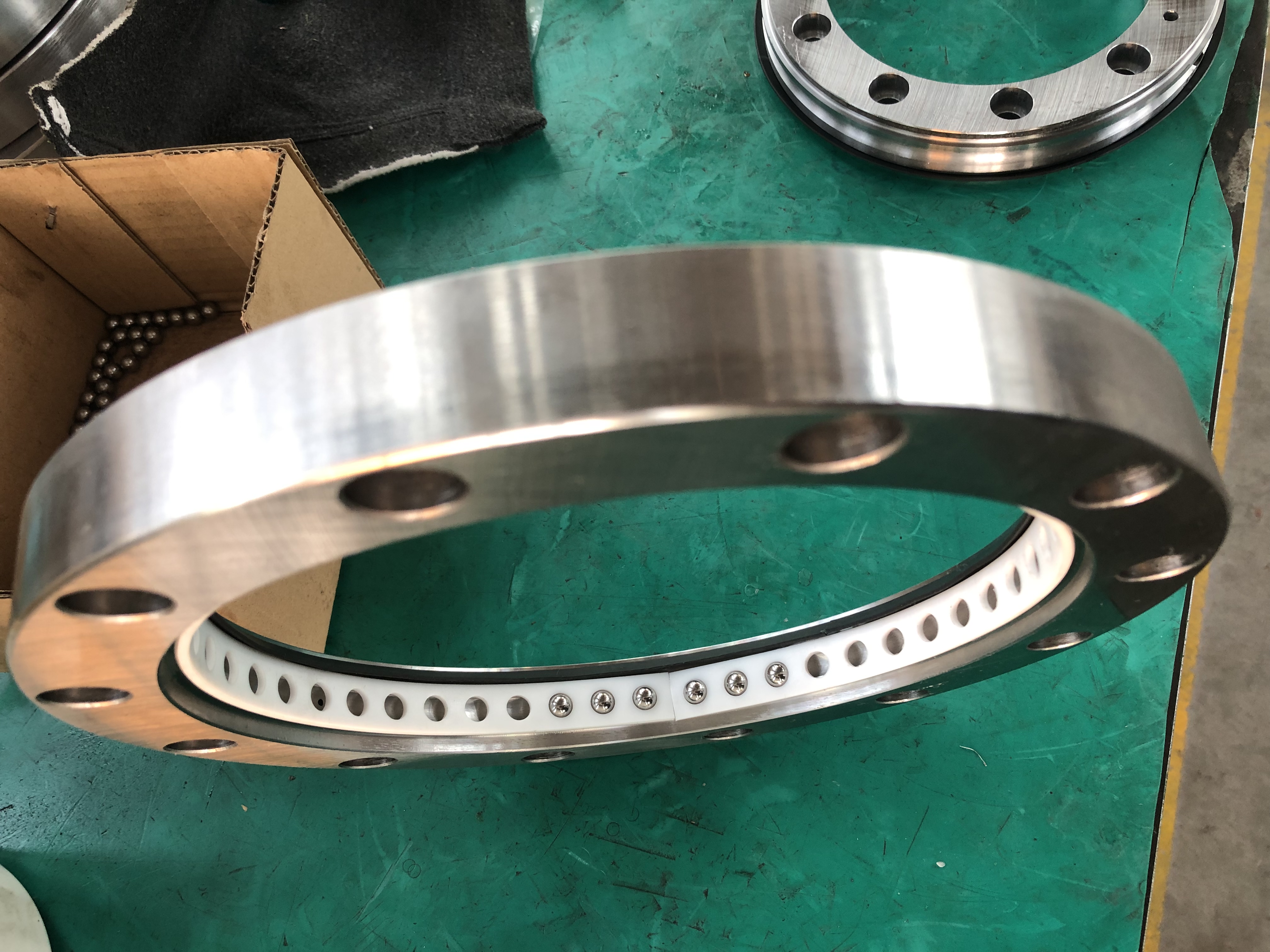

Slewing bearing processing technology

DZE Bearings - Precision Bearings and Special Bearings Manufacturer.

DZE Bearings- custom bearing manufacturer

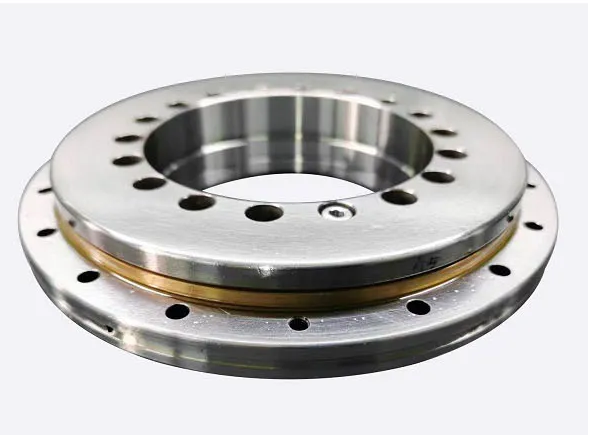

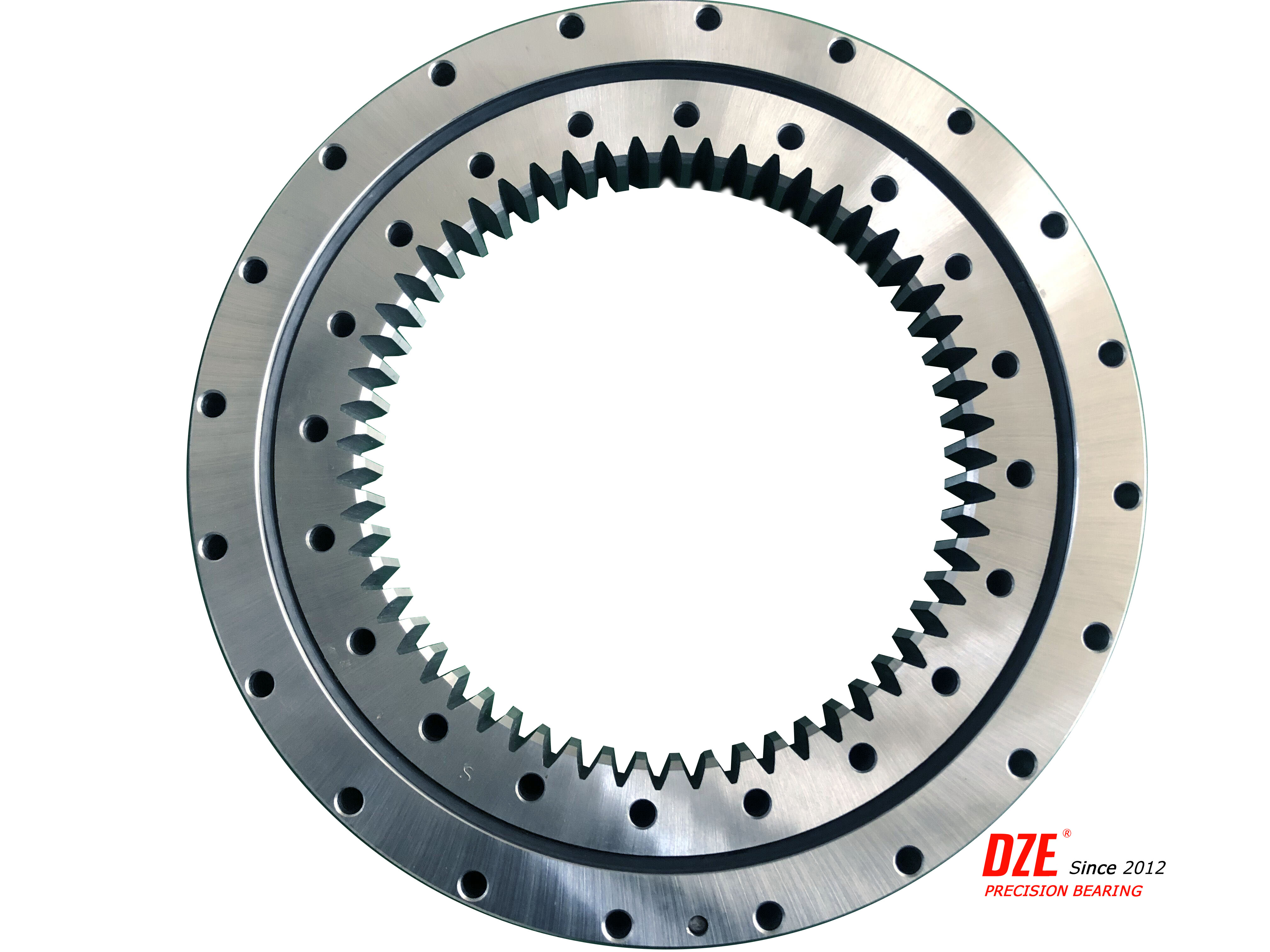

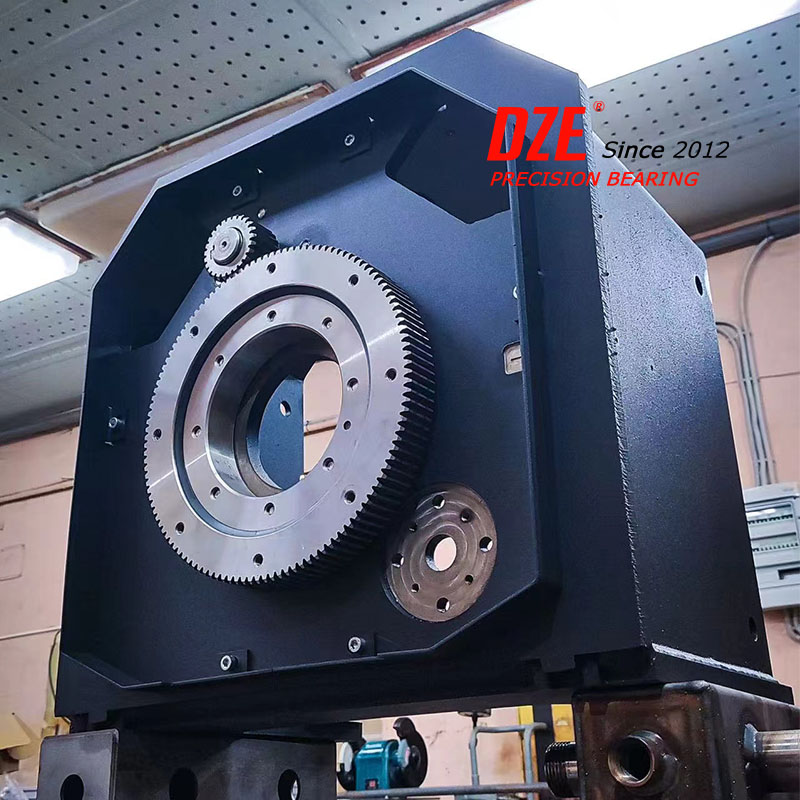

Precision bearings are an important mechanical part, and the process is an important factor in manufacturing precision bearings. The process will vary depending on the bearing model and customer needs.We provide slew bearing design, cross roller bearing design, YRT slew bearing design;

Designed according to user needs, the raw materials are forged into bearing blanks with initial shapes through forging processes.

Use lathes and other machine tools to turn bearing blanks into bearing parts such as outer and inner rings, rollers, and cages of precise size and shape.

The finished bearing parts are heat treated, including quenching and tempering, to improve the hardness, wear resistance and strength of the material.

The heat-treated bearing parts are hardness tested to ensure that they meet the hardness value required by the design.

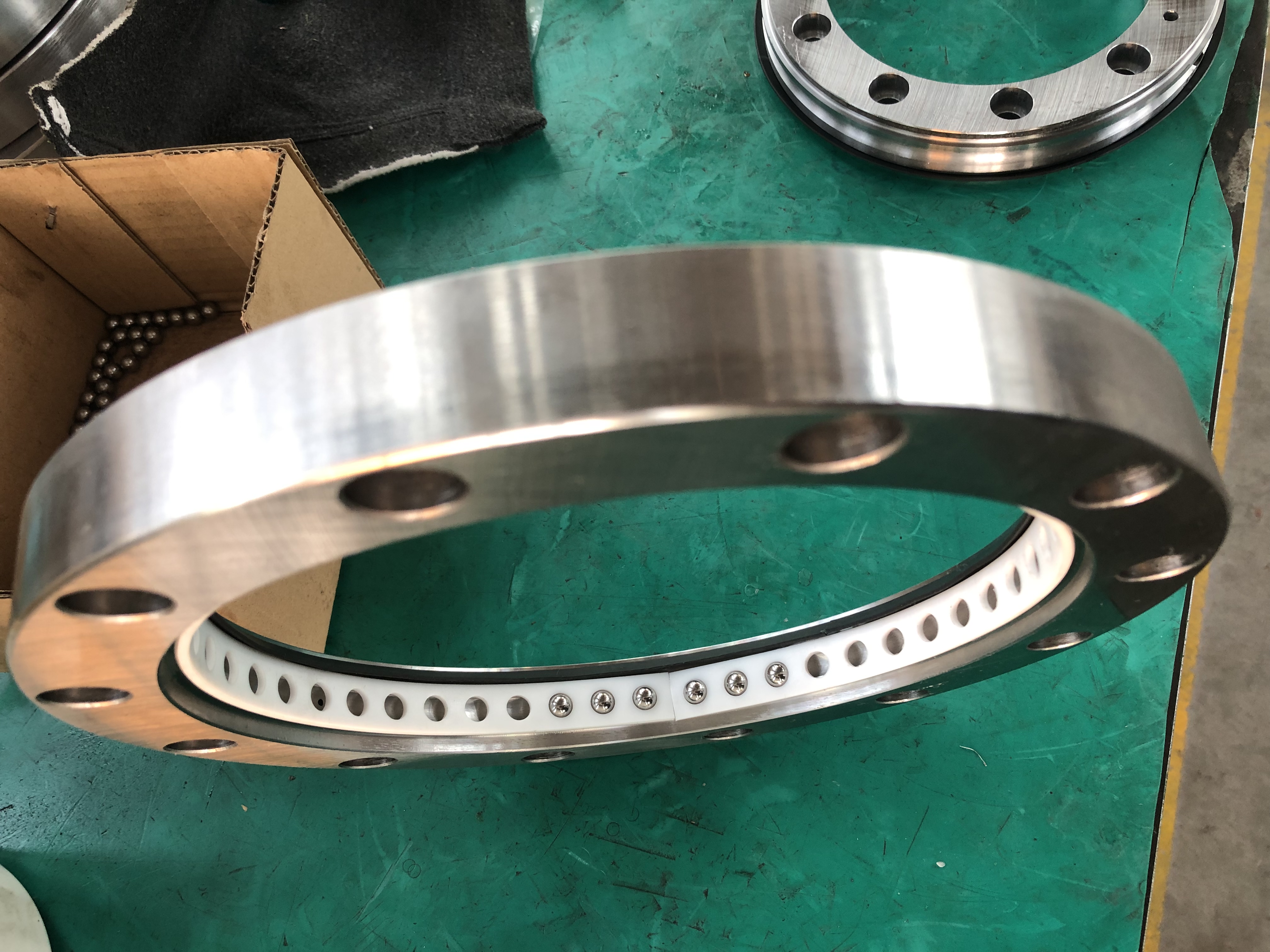

Grind the hardened bearing parts to improve their precision and surface quality. (Including grinding of outer rings, inner rings and rollers)

Assemble the ground bearing parts according to the assembly process, including installing the rollers between the inner and outer rings, and installing the cage and other components.

Strictly inspect the assembled bearings to check the appearance quality, dimension measurement, bearing friction test, etc. to ensure that the bearings meet the quality standards.

The qualified bearings are packaged with appropriate packaging materials to ensure that the bearings are free of damage and convenient for transportation and storage.

Choose the appropriate logistics service, track the logistics status after delivery, and confirm after the customer receives the goods. This process ensures the safe and efficient delivery of bearings from the warehouse to the customer.

Dongzhou Bearings - China Manufacturer of Precision Turntable Bearings, Precision Cross Roller Bearings, and YRT Turntable Bearings

Contact Us Mobile:+86 13700810892

Contact: Manager Zhao Company landline:+86 0379-64850932

Company address: No. 11, Shuangxiang South Road, Luoxin Industrial Cluster Zone, Xin'an County, Luoyang City, China (2 kilometers west of Jianxi Expressway Exit)