The permissible temperature range of the slewing connection is -45°C to +150C. If the application temperature of the component exceeds this range, please be sure to consult our technical department, Tel: 8613700810892

For some precision Crossed roller bearings that require continuous uninterrupted operation, they can only be stopped or locked for a period of time during maintenance work, and this pause can only last for a few hours. When performing maintenance work on custom ball bearings, please pay attention to: Maintenance work should be completed as soon as possible and unnecessary pauses should be avoided as much as possible. Special attention should also be paid to wind turbine bearings. The wind speed should not exceed 4 m/s to avoid damage to the rotor bearings.

When the rotor bearings are stopped, they should also be able to rotate easily and be in an automatic lubrication state. To ensure this requirement, the wind turbine equipment should be adjusted to a minimum speed of 0.5 U/min.

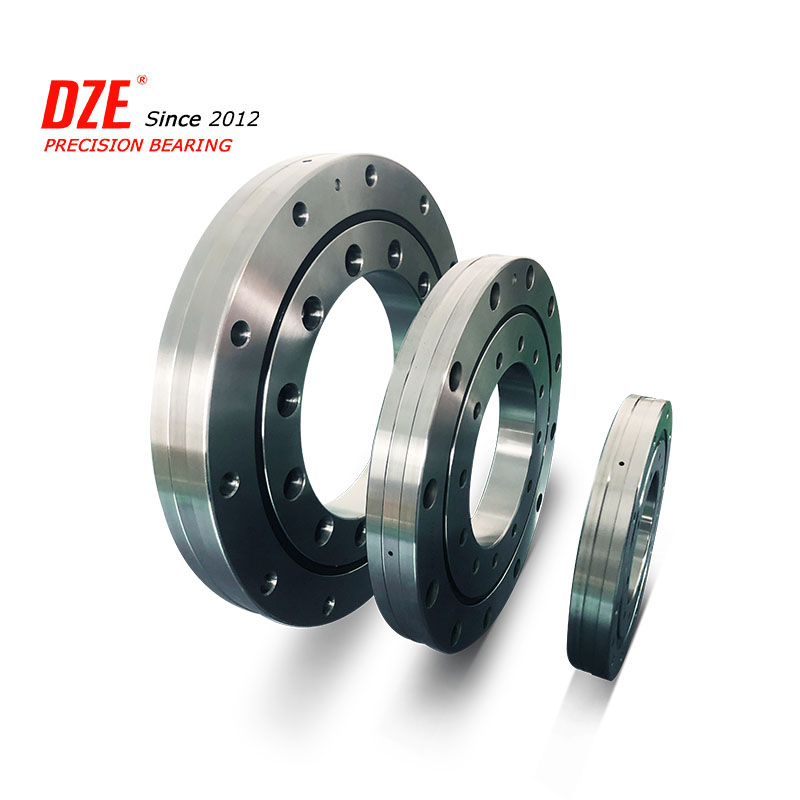

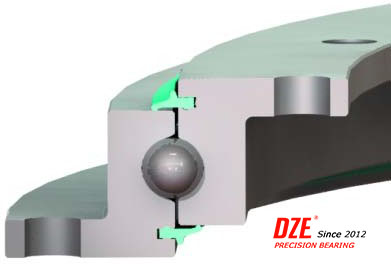

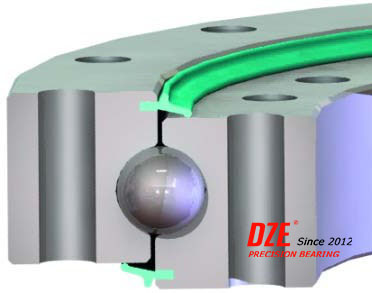

LYDZ 00-XXX Gearless Precision Slewing Bearing.Four-point contact ball structure, giant cross-section, can reduce end face runout by applying preload.Models include:

VSU200414;VSU200314;VSU200544;VSU200644;VSU200744;VSU200844;VSU200944;VSU201094;

33-0411-01;33-0541-01;;33-0641-01;33-0741-01;33-0841-01;33-0941-01;33-1091-01;

12740001;12750001;12770001;12775001;12780001;12785001;12790001;16289001;16389001;16290001;16291001;

10-16 0100/0-08000;10-20 0311/0-02002;10-20 0411/0-02012;10-20 0541/0-02022;10-20 0641/0-02032;10-20 0741/0-02042;10-20 0841/0-02052;10-20 0941/0-02062;10-20 1091/0-02072;

NB1.20.0314.200-1PPN ;NB1.20.0414.200-1PPN ;NB1.20.0544.200-1PPN ;NB1.20.0644.200-1PPN ;NB1.20.0744.200-1PPN ;NB1.20.0844.200-1PPN ;NB1.20.0944.200-1PPN ;NB1.20.1094.200-1PPN ;

NB1.20.0314.201-2PPN ;NB1.20.0414.201-2PPN ;NB1.20.0544.201-2PPN ;NB1.20.0644.201-2PPN ;NB1.20.0744.201-2PPN ;NB1.20.0844.201-2PPN ;NB1.20.0944.201-2PPN ;NB1.20.1094.201-2PPN ;

LYDZ 01-XXX Gearless Precision Slewing Bearing.Four-point contact ball structure, giant cross-section, can reduce end face runout by applying preload.Models include:

VSA200414;VSA200544;VSA200644;;VSA200744;;VSA200844;VSA200944;;VSA201094;

VLA200414;VLA200544;;VLA200644;VLA200744;VLA200844;;VLA200944;VLA201094;

21-0411-01;21-0541-01;21-0641-01;21-0741-01;21-0841-01;21-0941-01;21-1091-01;

31-0411-01;31-0541-01;31-0641-01;31-0741-01;31-0841-01;31-0941-01;31-1091-01;

MTE-145;MTE-145T;MTE-145X;MTE-210;MTE-210T;MTE-210X;MTE-265;MTE-265T;MTE-265X;MTE-324T;MTE-415;MTE-415T;MTE-470;MTE-470T;MTE-540;MTE-540T;MTE-590;MTE-590T;MTE-705;;MTE-705T;MTE-730;MTE-730T;MTE-870;MTE-870T;

16305001;16306001;16307001;12440001;16308001;12288001;16309001;16310001;16311001;16312001;16313001;16314001;16315001;16316001;16317001;

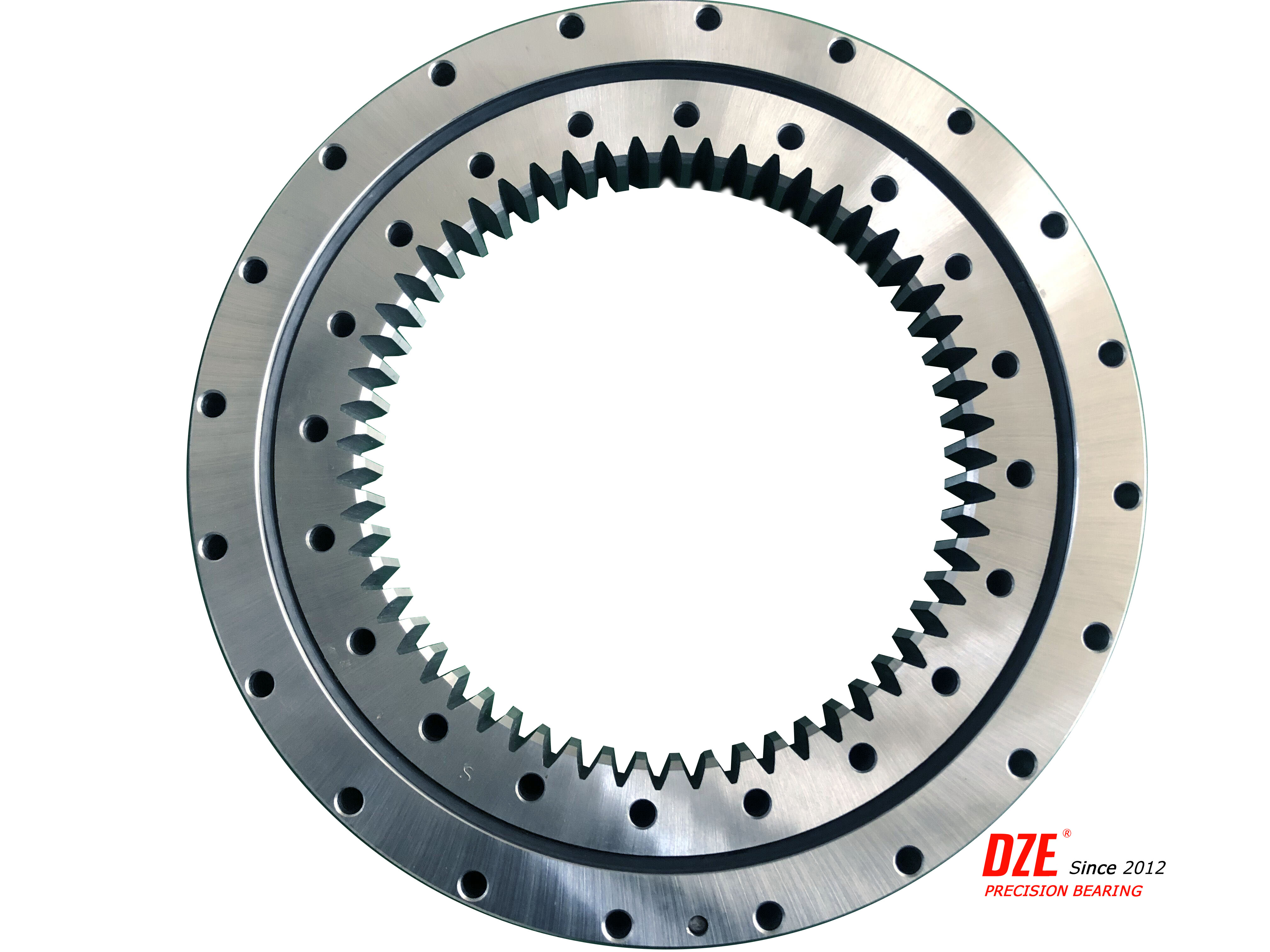

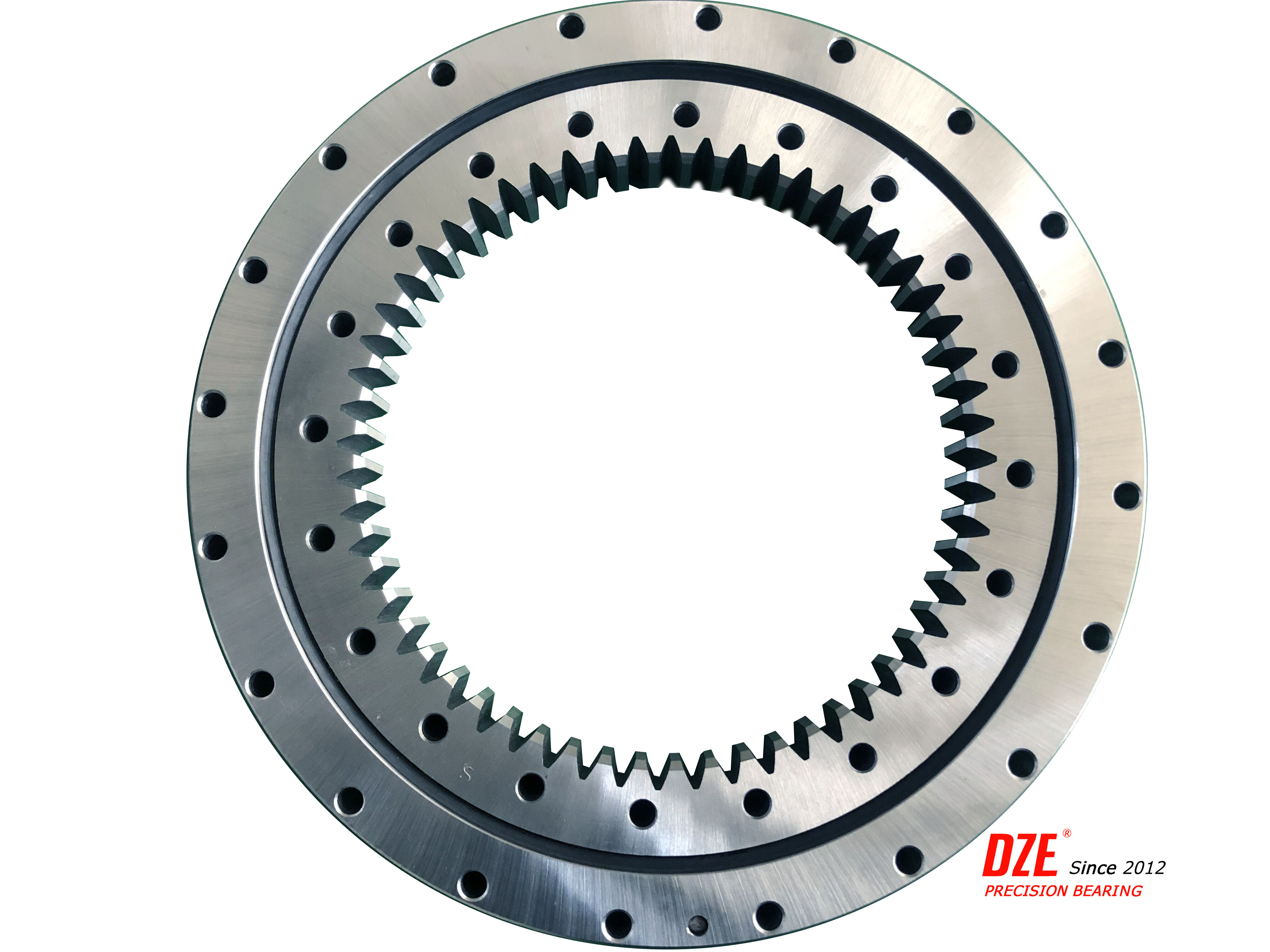

LYDZ 03-XXX.Internal gear structure precision custom ball bearings.DZE internal gear slewing bearing is divided into single row ball and double row ball. You can choose the appropriate structure according to your needs.Models include:

VSI200414;VSI200544;VSI200644;VSI200744;VSI200844;VSI200944;;VSI201094;

VLI200414;VLI200544;VLI200644;VLI200744;VLI200844;VLI200944;VLI201094;

22-0411-01;22-0541-01;22-0641-01;22-0741-01;22-0841-01;22-0941-01;22-1091-01;

32-0411-01;32-0541-01;32-0641-01;32-0741-01;32-0841-01;32-0941-01;32-1091-01

HS6-16N1Z;HS6-21N1Z;HS6-25N1Z;HS6-29N1Z;HS6-33N1Z;HS6-37N1Z;HS6-43N1Z;

HT10-30N1Z;HT10-36N1Z;HT10-42N1Z;HT10-48N1Z;HT10-54N1Z;HT10-60N1Z;

16274001;16275001;16276001;16277001;16278001;16279001;16280001;16281001;

Customized Crossed roller bearings

In addition to manufacturing the standard bearings mentioned above, DZE has extensive experience in producing custom/special bearings and components. This experience enables DZE to produce a variety of products that meet customer needs. The ball and roller bearings shown below are only examples of our custom bearing capabilities. We hope it will inspire your imagination to find the most suitable solution.

Thin-section cross roller bearings have higher stiffness, improved dynamic load performance, lower torque, lighter weight, and more space saving. The rollers should be oriented in the direction that maximizes load performance and fatigue life. Designs with similar configuration characteristics can provide product sizes ranging from 15 inches to more than 90 inches.

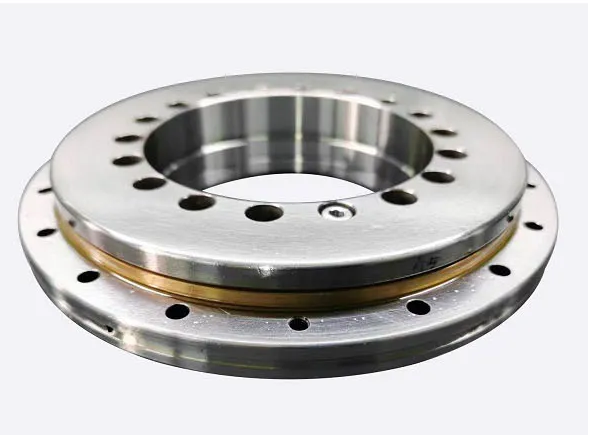

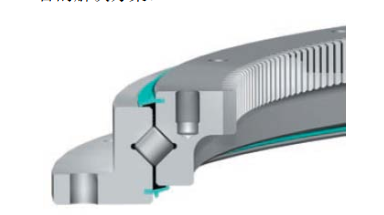

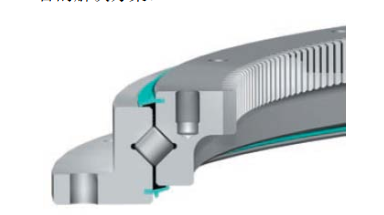

Three-ring, two-row roller bearings have two integral gear rings, one inside and one outside, as shown. This construction, combined with other precision components, allows the rings and their associated structures to operate precisely, smoothly, independently, and synchronously. The use of spacers increases the bearing's limiting speed, and combined with low-friction seals, it minimizes rotational resistance. This construction reduces the number of redundant components that perform the same function.