Bearing damage analysis

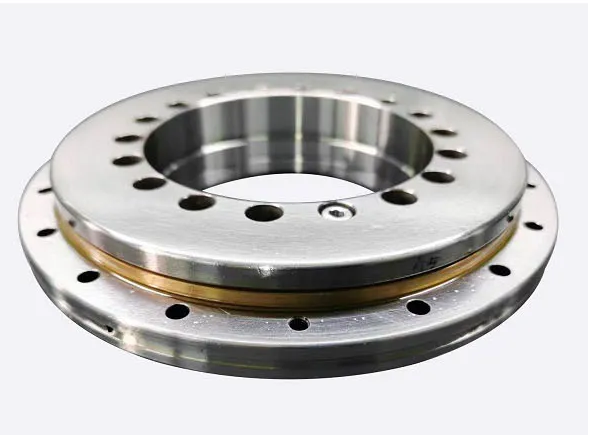

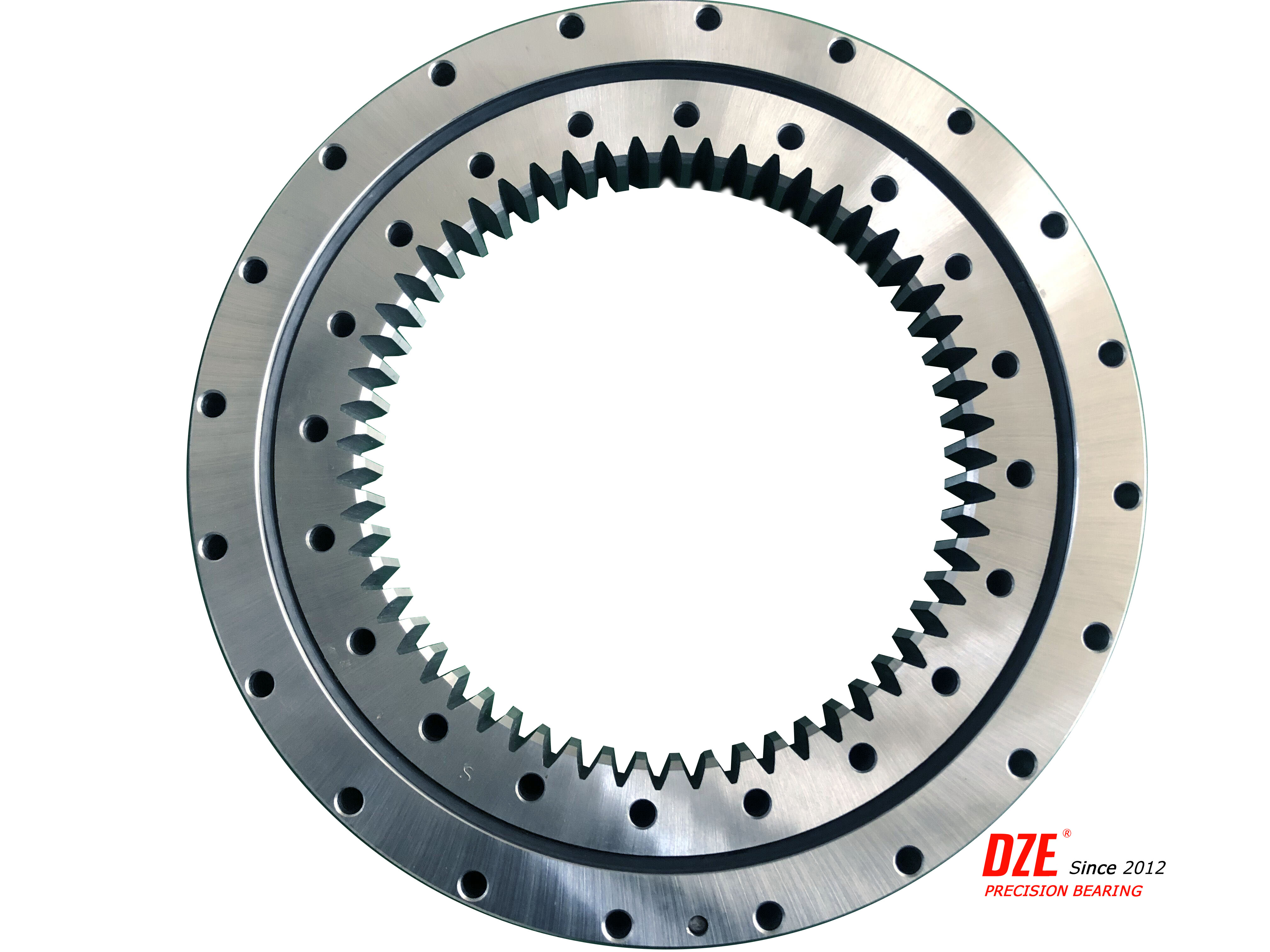

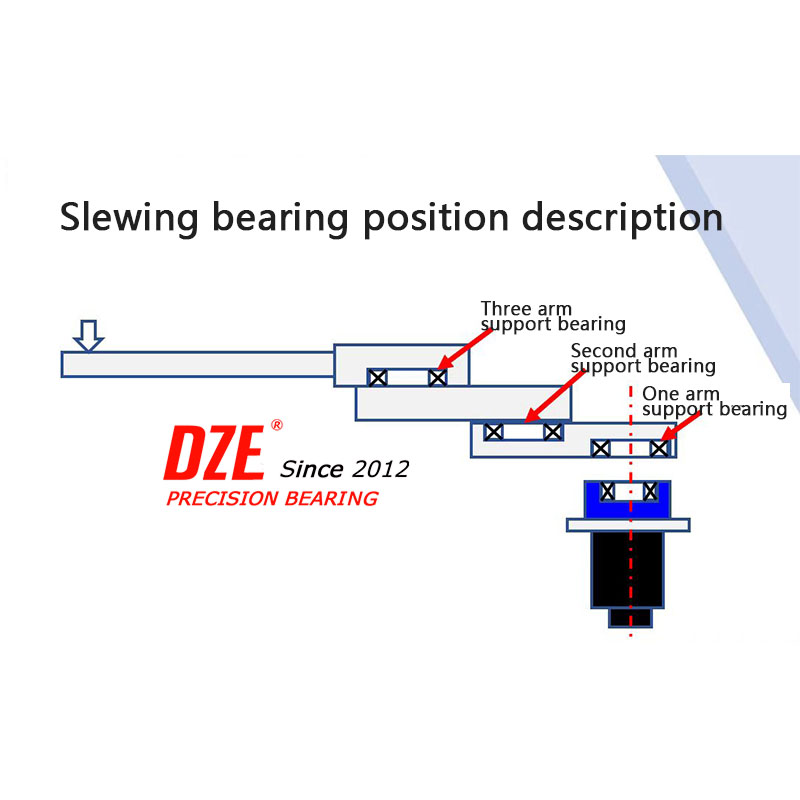

On April 27, 2025, the DZE sales team received an inquiry from a customer that the cross roller bearings of their three-arm rotating mechanism were stuck and stopped, which had a great impact on the coordination of the entire enterprise chain.The bearing model is: 88.0352.00DD00 Crossed roller bearings series;The overall diagram of the rotary mechanism is as follows:

The mechanism is a three-axis swing arm lifting structure, using three sets of cross roller bearings, the models are:88.0352.00DD00;88.0550.00DD00;The cargo weighed 10 tons. During use, the cross roller bearing was seriously damaged because it could not fully bear the weight of the cargo.

DZE engineers conducted a bearing damage analysis, found out the problem, and solved the urgent problem for the customer.

Changing Materials

Since the selected models are 88.0352.00DD00 and 88.0550.00DD00, the internal structure is a cross roller bearing, which has a very large load-bearing capacity. However, because the bearing material is 42aCrMo, this material is only suitable for raceway surface quenching, which leaves a fundamental problem that cannot be solved.

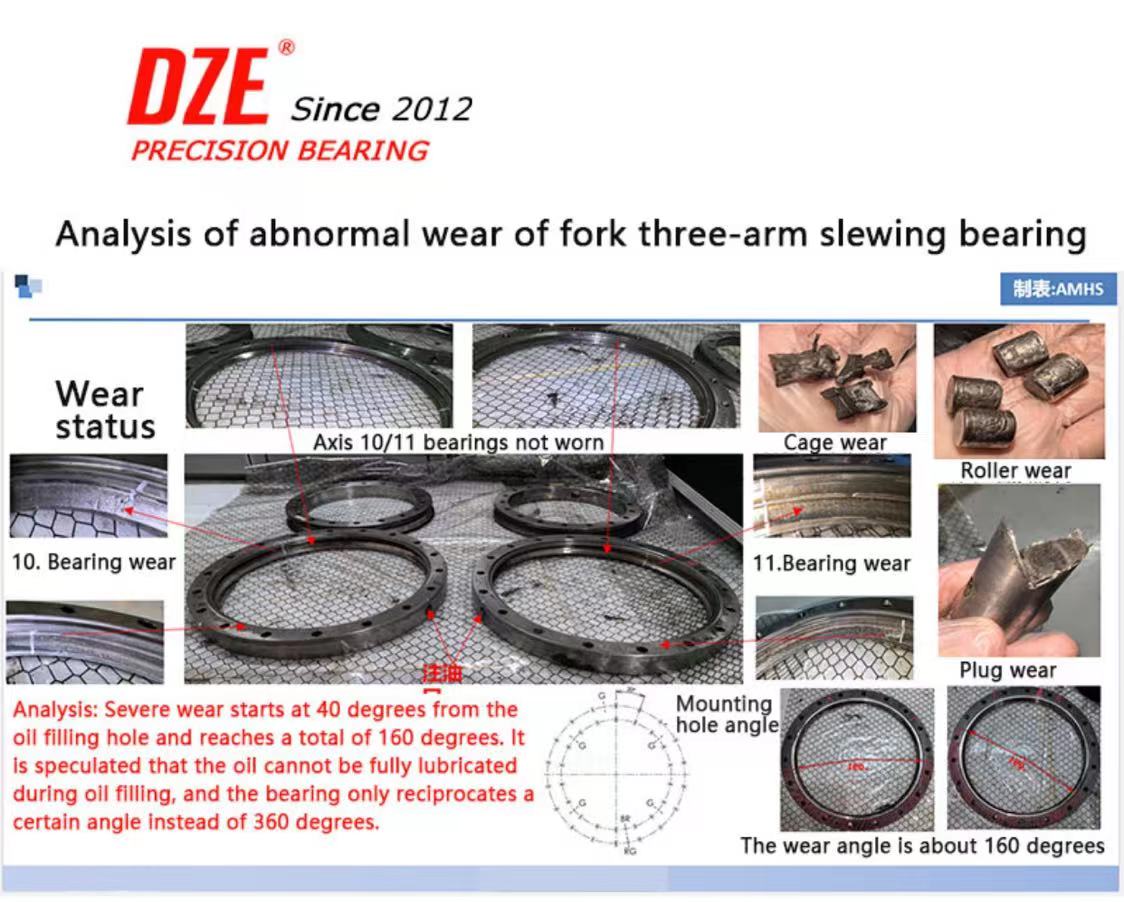

The reason for the serious wear of the rollers and the damage of the raceway of the cross roller bearings is that the raceway hardness is not enough and the bearing material is not selected correctly.

As we all know, a soft pocket will be left when the 42CrMo raceway surface is quenched, and "S" is used as a mark. It is because of this soft pocket that it has caused serious disasters to the entire host.After strict Bearing damage analysis .We provided customers with improvement suggestions, changing 88.0352.00DD00 Cross Roller Bearings 42CrMo material to bearing steel material - code GCr15SiMn.

This avoids the appearance of soft pockets in the raceway, and the crossed roller bearing will not be subjected to force at the soft pockets during the rotation process.

Optimized design

1: Change the material of the cross roller bearing 88.0352.00DD00 to: bearing steel GCr15SiMn; increase the bearing rigidity and wear resistance;

2: Increase the number of lubricating oil holes in the inner and outer rings;

3: Bearing damage analysis-Remove the retainer, increase the number of rollers, and increase the axial dynamic load rating, which can increase about 10 rollers;

Perfect results

After strict calculations by DZE engineers, the improved cross roller bearings 88.0352.00DD00 axial load capacity increased by 20%, fully meeting the customer's requirements, while the bearing life was increased by nearly 3 times.

In addition to manufacturing, DZE precision bearings also provide you with after-sales services to protect your host! DZE engineer WhatsApp: +8613700810892