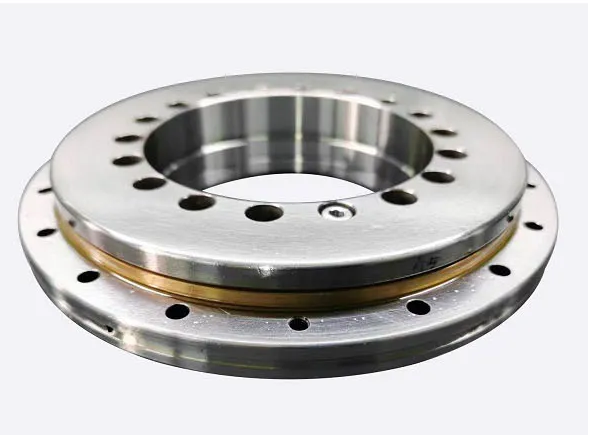

RU Series |RU124X| Bearing CRBE8022A

Features:

1. High Precision: Accuracy reaches P5/P4/P2 levels.

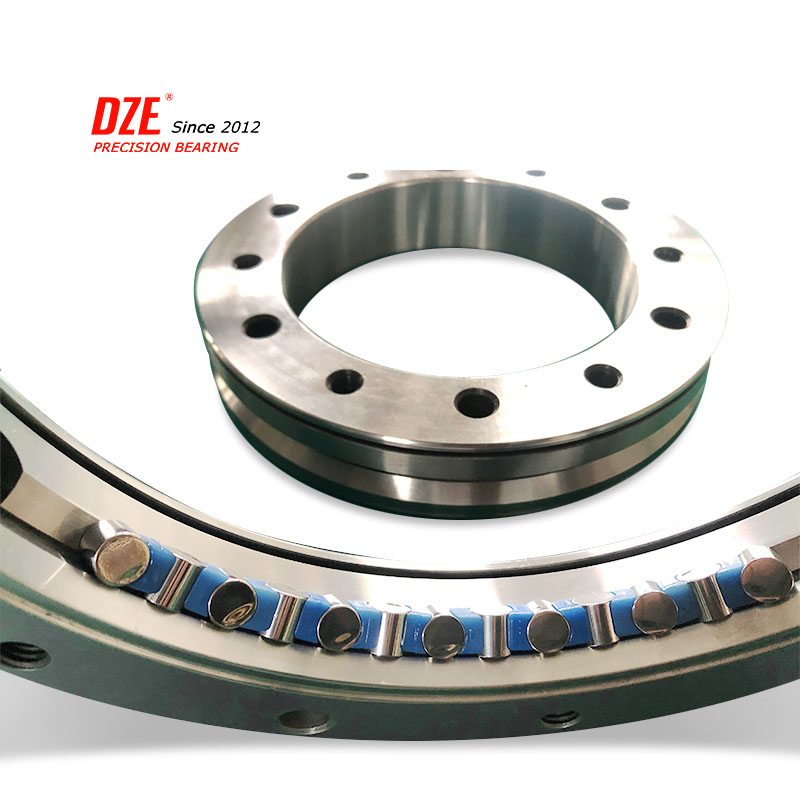

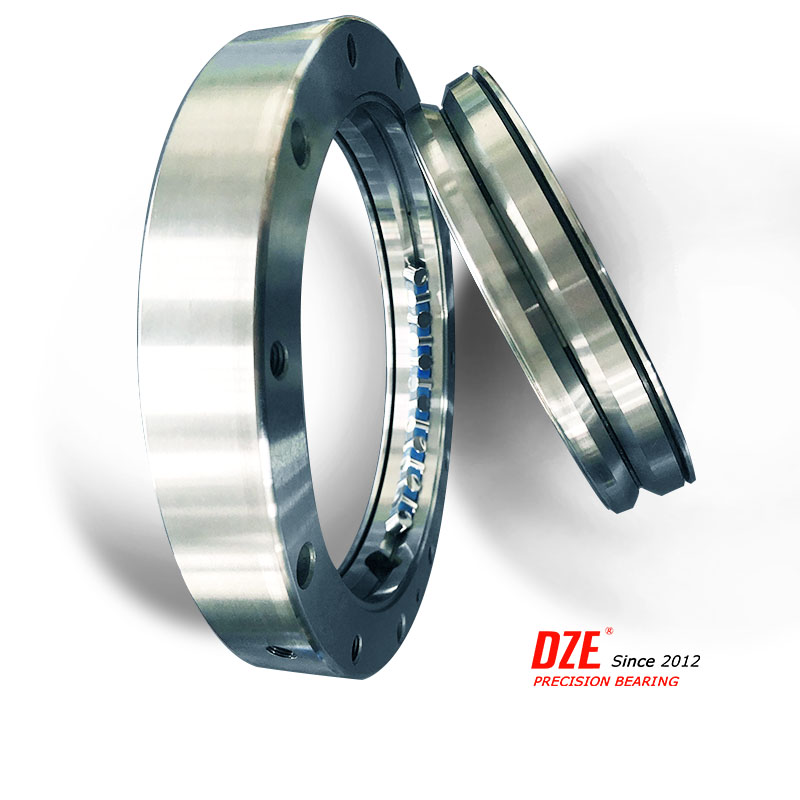

2. Long Life: DZE crossed roller bearings are preloaded. The inner and outer rings are minimized to minimize dimensions. Their construction features a split outer ring and a single-piece inner ring, making them suitable for applications requiring high inner ring rotational accuracy.

3. High Load Capacity: Capable of withstanding axial, radial, and tipping loads.

4. Compact Size: This bearing is compact, saving space in the main engine.

5. Material: High-quality bearing steel, with material analysis available.

6. Hardness: Through-hardened HRC 60-64

Model | Dimensions(mm) | Carrying(KN) | Weight | Same Model |

Inner | Outer | Height |

d | D | H | C | Co | kg | THK | IKO |

CRBE1008 | 10 | 52 | 8 | 2.91 | 2.43 | 0.12 | RU28 | CRBF108AT |

CRBE2012 | 20 | 70 | 12 | 7.35 | 8.35 | 0.29 | RU42 | CRBF2012AT |

CRBE2512 | 25 | 80 | 12 | 8.61 | 10.6 | 0.4 | RU52 | CRBF2512AT |

CRBE3515 | 35 | 95 | 15 | 17.5 | 22.3 | 29.5 | RU66 | CRBF3515AT |

CRBE5515 | 55 | 120 | 15 | 20.3 | 29.5 | 1 | RU85 | CRBF5515AT |

CRBE8022 | 80 | 165 | 22 | 33.1 | 50.9 | 2.6 | RU124 | CRBF8022A |

CRBE8022A | RU124G | CRBF8022AD |

CRBE8022B | RU124X | CRBF8022AT |

CRBE9025 | 90 | 210 | 25 | 49.1 | 76.8 | 4.9 | RU148 |

|

CRBE9025A | RU148G |

|

CRBE9025B | RU148X |

|

CRBE11528 | 115 | 240 | 28 | 80.3 | 135 | 6.8 | RU178 |

|

CRBE11528A | RU178G |

|

CRBE11528B | RU178X |

|

CRBE16035 | 160 | 295 | 35 | 104 | 173 | 11.4 | RU228 |

|

CRBE16035A | RU228G |

|

CRBE16035B | RU228X |

|

CRBE21040 | 210 | 380 | 40 | 156 | 281 | 21.3 | RU297 |

|

CRBE21040A | RU297G |

|

CRBE21040B | RU297X |

|

CRBE35045 | 350 | 540 | 45 | 222 | 473 | 35.4 | RU445 |

|

CRBE35045A | RU445G |

|

CRBE35045B | RU445X |

|

ABOUT DZE

DZE Bearing is China bearing manufacturers . established in 2012 is a precision bearing manufacturer, factory located in Luoyang, China, the thousand-year-old imperial capital. Luoyang is the capital of bearings and the city of peonies, where one hundred and three emperors made their capital. Has 10 major bearing manufacturers. Our manufacturing process:

Our Advantage-RU445 bearing

&:Serve The Word-Professional logistics to reach any place

&:IN-Stock-DZE has most of its inventory in stock and can ship to you on the same day,

&:24-Hour Service-365-day online service throughout the year

&:Customization-Customize non-standard bearings according to requirements

Production process-RU445 bearing

Production process-RU445 bearing

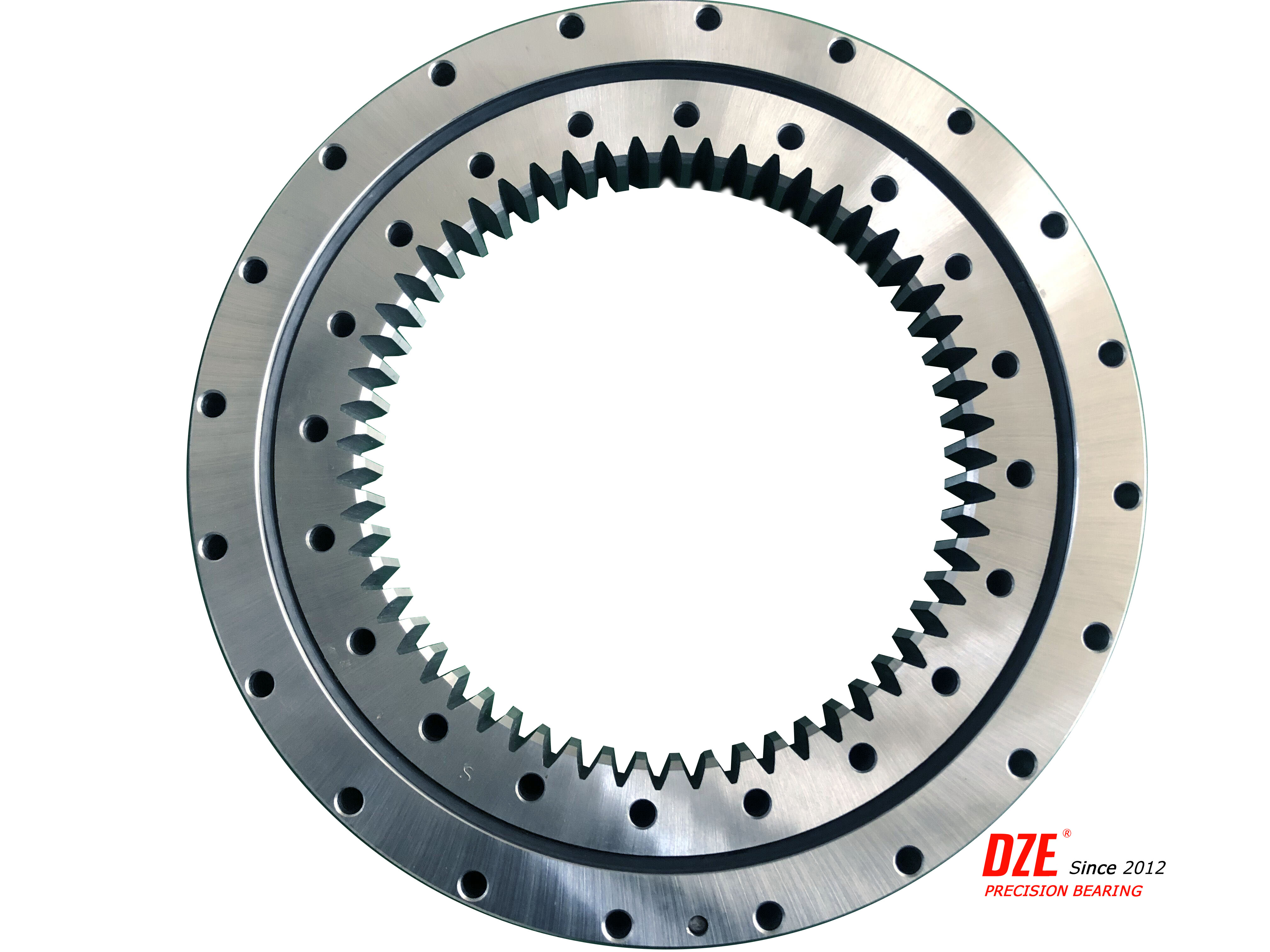

Customization-RU series Bearings-RU445 bearing

DZE provides customized services for any bearing size, including slewing bearings, Cross Roller Bearing ,toothless structures, external gear structures, internal gear structures. Single row ball, single row roller, double row ball, double row roller, precision gears, spur gears, helical gears, herringbone gears, arc gears, worm gears.

Customization of special materials: 13 years of manufacturing experience is a great asset. DZE special materials include: stainless steel :9Cr18, 9Cr18Mo; S165M; TC4 titanium alloy, hard aluminum; nylon. Nickel alloy, aluminum bronze.

Bearing heat treatment includes: normalizing, annealing, quenching and tempering, cold treatment, tempering, quenching, and accessory tempering;

The precision turntable bearings produced by DZE Bearing generally undergo quenching and tempering, tempering stabilization, surface quenching and other heat treatment processes to improve the internal structure; the quenching and tempering hardness is generally HB229-269; the surface quenching hardness is generally HRC56-62°;

Generally suitable for precision turntable bearings, external gear turntable bearings, internal gear turntable bearings, etc.;

DZE Bearing bearing steel heat treatment includes: annealing and quenching, the hardness of bearing steel after quenching is HRC60-65°; generally suitable for RU series cross roller bearings, XSU series cross roller bearings, RB series cross roller bearings, and YRT three-row combined turntable bearings.

DZE precision bearing talents have been vigorously developed. There are 15 senior engineers and 5 postgraduates. The company has cooperated with Luoyang LYC Bearing Co., Ltd. and Luoyang ZYS Bearing Research Institute for many years to jointly formulate industry standards and national technical standards, which has made a significant contribution to the development of the company.

DZE certifications are 3.1, 3.2, ABS, CCS. The company team has technology and rich experience in the bearing industry. With a global network, we can solve any bearing problem for you. DZE bearings are a perfect replacement for the most common and well-known brands.

DZE technical service content:

Provide technical support, solution customization, and design of assembly drawings before sales;

During sales: DZE provides strict inspection and record keeping for each process;

After-sales service: Solve all your needs and technical problems 24 hours a day, online contact: Whats app: +8613700810892