Types Of Slewing Bearing

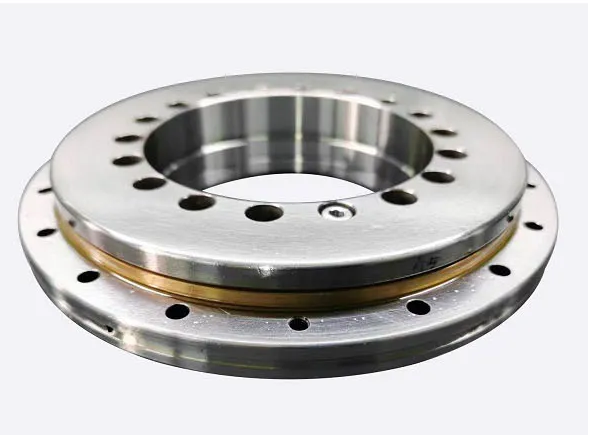

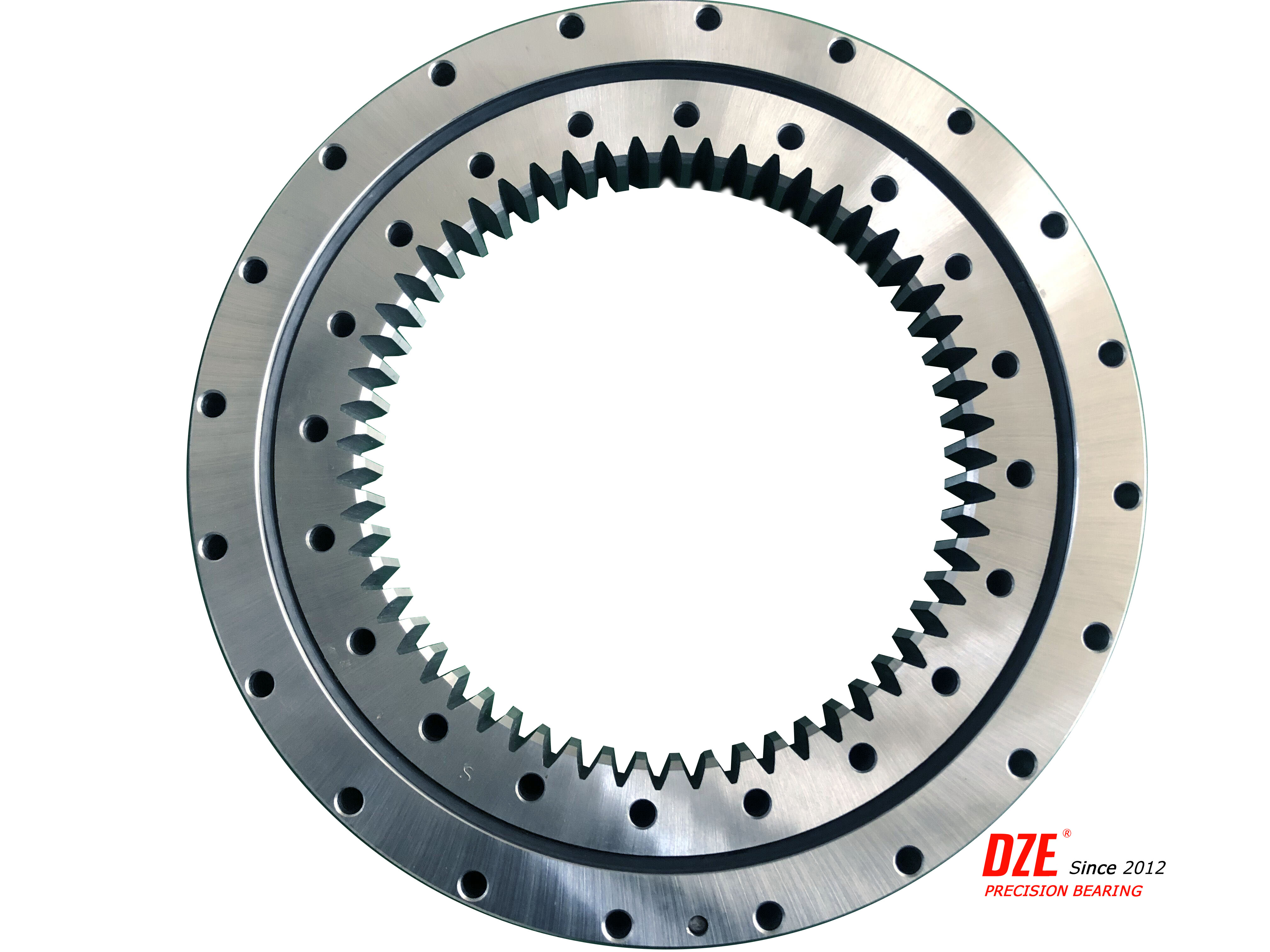

As key components of machine tools, the performance of slewing bearing and cross roller bearing will directly affect the parameters of machine tool rotation accuracy, speed, rigidity, temperature rise and noise, which will in turn affect the processing quality of workpieces, such as the dimensional accuracy of parts, surface roughness and other indicators.

Therefore, high-performance bearings must be used. The precision of bearings used on machine tool spindles should be ISO P5 or above (P5 or P4 is the ISO precision level, usually from low to high as P0, P6, P5, P4, P2), and for spindle bearings of high-speed and high-precision machine tools such as CNC machine tools and machining centers, ISO P4 or above precision is required; spindle bearings include angular contact ball bearings, tapered roller bearings, and cylindrical roller bearings.

slewing bearingcross roller bearingbearing manufacturers

Email

More